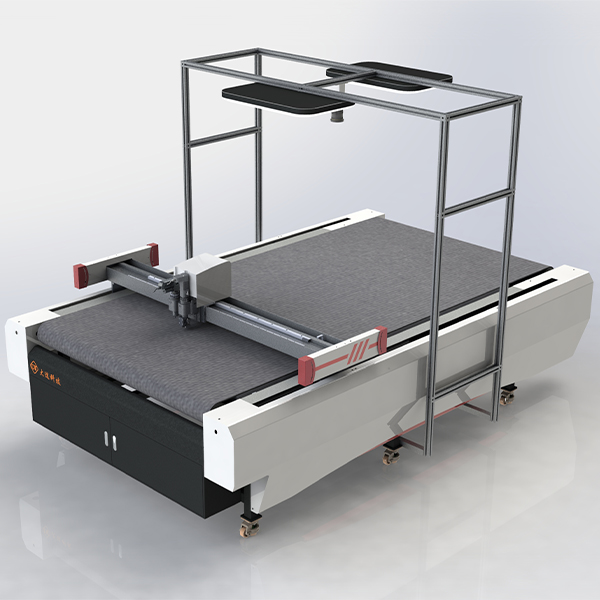

Wholesale Carbon Fiber Cutting - Home Carpet Industry Digital Cutter – Datu Detail:

Standard carpet fiber raw materials are natural fibers, chemical fibers, and blends. Among them, natural fibers include wool, silk, cotton, jute, etc.; chemical fibers include viscose staple fiber, nylon BCF filament, and staple fiber, acrylic staple fiber, polypropylene BCF filament and staple fiber, and polyester staple fiber; blended with wool/nylon, wool/viscose, wool/acrylic, wool/polyester, and wool/jute. They are the typical soft materials. To achieve industrial upgrading and improve production efficiency and capacity, advanced cutting equipment has become the general trend.

The vibrating knife cutting machine is a relatively widely used processing equipment in the flexible material cutting process. It uses the upper and lower high-frequency vibration of the blade to cut. It has high precision, fast cutting speed, and is not limited by the cutting pattern. It can be automatically loaded and unloaded. Intelligent typesetting, smooth incision, low processing cost and other characteristics, gradually improve or replace the traditional flexible cutting process equipment.

|

Equipment Model |

DT-2516A |

|

Scope Of Work |

2500x1600mm |

|

Drive System |

Imported Mitsubishi Servo Motor Drive |

|

Transmission System |

Pmi Linear Guide Rail, Precision Rack Drive |

|

Maximum Cutting Speed |

1800mm/s |

|

Cutting Material |

Silk, Cotton,Viscose Staple Fiber, Nylon Bcf Filament Etc. |

|

Cutting Tools |

Vibrating Knife, Round Knife Etc. |

|

Cutting Thickness |

0.1-30mm (Subject To Specific Materials) |

|

Cutting Accuracy |

±0.01mm |

|

Repetition Accuracy |

±0.03mm |

|

Feeding Method |

Automatic Feeding |

|

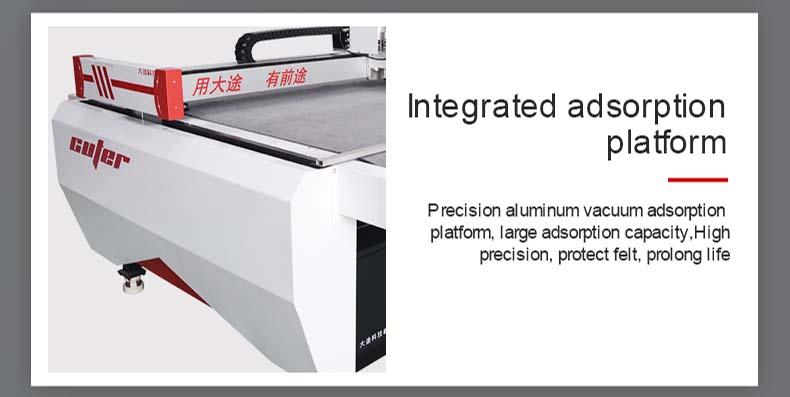

Fixing Method |

All Aluminum Table Vacuum Adsorption |

|

Transmission Interface |

Usb/u Disk/Network |

|

Power Supply And Power Of Cutting Equipment |

220v/50hz 2.5kw |

|

Power Supply And Power Of Vacuum Pump |

380v 7.5kw/9kw (Optional) |

|

Positioning Method |

Infrared Laser, Ccd Camera (Optional) |

|

Safety Device |

Infrared Laser Induction, Safe And Stable |

|

Pneumatic Fittings |

Festo, Germany/Yadek, Taiwan |

|

Electrical Fittings |

Chint/Delixi |

Datu Technology’s vibrating knife cutting machine has a comprehensive cutting plan for carpets, including cutting of natural fibers, chemical fibers and blended materials. In the ever-increasing variety of commodities, floor coverings can be produced individually, with high-precision and automated production methods, and with short production cycles. It uses the most advanced technology and the highest quality components. The flexibility, reliability and quality of Datu Technology’s vibrating knive cutting machine is much better than other machining.

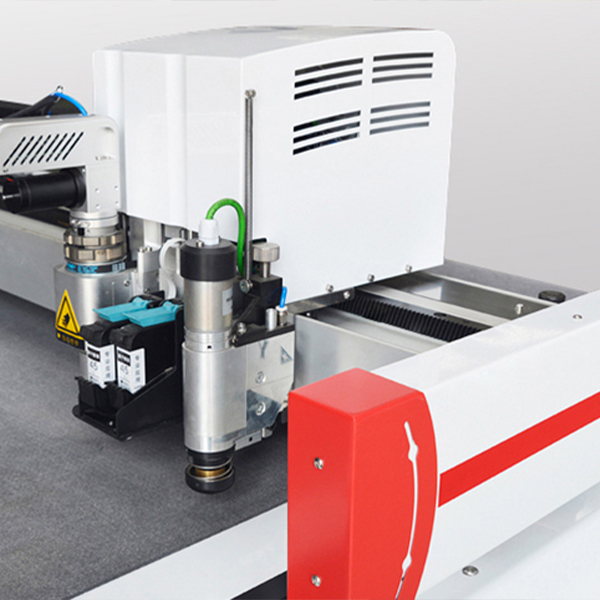

1. There are more cutting configurations for round cutter, vibrating cutter and pneumatic cutter.

2. 1800MM/S high speed, the precision of repeated positioning to the cutting origin is ±0.01mm.

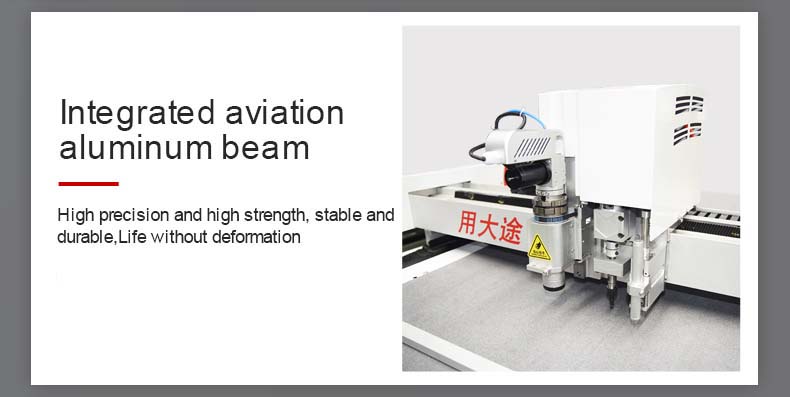

3. Mitsubishi servo motors, Taiwan Hindwin guide rails and other brand electrical components, double rack machines are more durable

4. Equipped with a large visual intelligent edge inspection system, cutting and proofing are faster.

5. One-click import of drawings, convenient for cutting, data import and direct cutting, no paper version is required. save time.

6. Support for multiple file formats (AI, PLT, DXF, CDR, etc.), making it more convenient to use and interact.

7. The cutting section is clean and smooth, without chips and burrs

8. Edge cutting can be performed according to the printing requirements of raw materials

Applicable tools: vibrating kinfe, round knife

Applicable models: DT-2516A

(1) One-year warranty policy.

(2) 7*24-hour online service.

(3) Provide lifetime free technology upgrade service.

(4) Free training in our factory, if time is not convenient, we can also provide complete training video.

(5) On-site technical support can be provided by negotiation.

Product detail pictures:

Related Product Guide:

Adhering into the theory of "quality, services, efficiency and growth", now we have gained trusts and praises from domestic and international shopper for Wholesale Carbon Fiber Cutting - Home Carpet Industry Digital Cutter – Datu, The product will supply to all over the world, such as: Slovenia, Serbia, Austria, We'll initiate the second phase of our development strategy. Our company regards "reasonable prices, efficient production time and good after-sales service" as our tenet. If you are interested in any of our products and solutions or would like to discuss a custom order, make sure you feel free to contact us. We've been looking forward to forming successful business relationships with new clients around the world in the near future.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.

-

Excellent Quality Twin Wall Sheets Cutting Mach...

-

Lowest Price For CNC Knife Cutter - Digital Cu...

-

Fixed Competitive Price Leather Plotter Cutter ...

-

2022 Wholesale Price Textiles Airdancers Cuttin...

-

OEM/ODM Supplier Kiss Cut Cutting Machine - Cn...

-

Factory Wholesale High Quality Oscillating Knif...