We now have a specialist, efficiency workforce to deliver excellent service for our purchaser. We always follow the tenet of customer-oriented, details-focused for Supply ODM One-Way Particleboard Bent Wood Engraving Machine, Bent Wood Chair Back Cutting and Hole Drilling Machine Bent Wood Furniture Pressing and Shaping Machine, Honesty is our principle, skilled procedure is our perform, service is our target, and customers’ satisfaction is our long term!

We now have a specialist, efficiency workforce to deliver excellent service for our purchaser. We always follow the tenet of customer-oriented, details-focused for China Oneway Particleboard Bent Wood Engraving Machine and Bent Wood Chair Back Cutting Hole Drilling Machi, Our company now has many department, and there have more than 20 employees in our company. We set up sales shop, show room, and product warehouse. In the meantime, we registered our own brand. We have tightened inspection for quality of product.

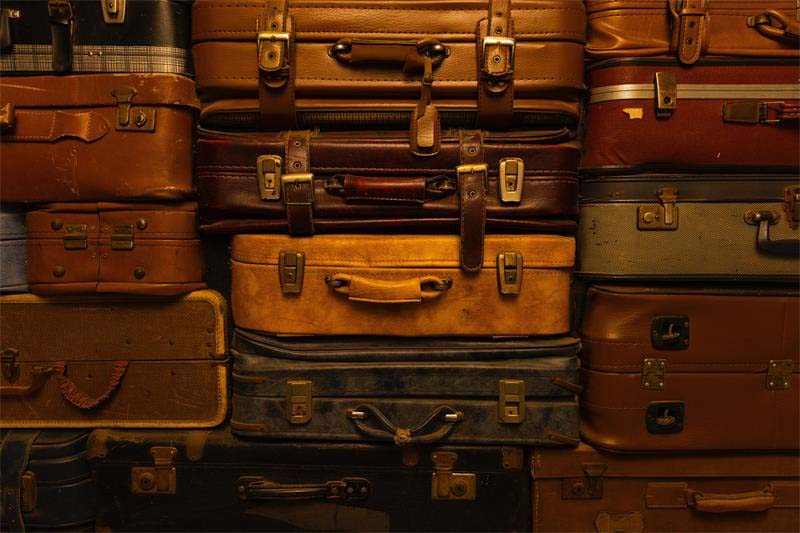

With the continuous development of the luggage and leather goods industry, the materials of this industry are also increasing, such as microfiber, genuine leather, regenerated leather, spunlace non-woven fabric, canvas, flannel, stitch-bonded non-woven fabric, wet non-woven fabric, spun-bond Non-woven fabrics, etc. are typical soft materials. To achieve industrial upgrading and improve production efficiency and capacity, it is necessary to use advanced cutting equipment.

Leather is a common material in our daily life, and leather products cover almost every aspect of our lives, such as leather bags, leather shoes, leather clothing, sofas, car seats, etc. It can be seen everywhere.

With the continuous upgrading of social consumption, human beings are not only satisfied with unadorned leather products. Faced with various complex patterns, the traditional tanning process has been difficult to meet the increasingly personalized needs.

The traditional leather processing method is not only time-consuming, labor-intensive, but also of poor quality. As a new leather processing method, laser cutting processing once occupied the mainstream of the leather processing market, but laser cutting is a thermal cutting method. Although the performance is mature and the price is cheap, with the country’s strict requirements for environmental protection, laser cutting leather is easy to produce smoke, odor, material burning, etc., do not meet environmental protection requirements.

|

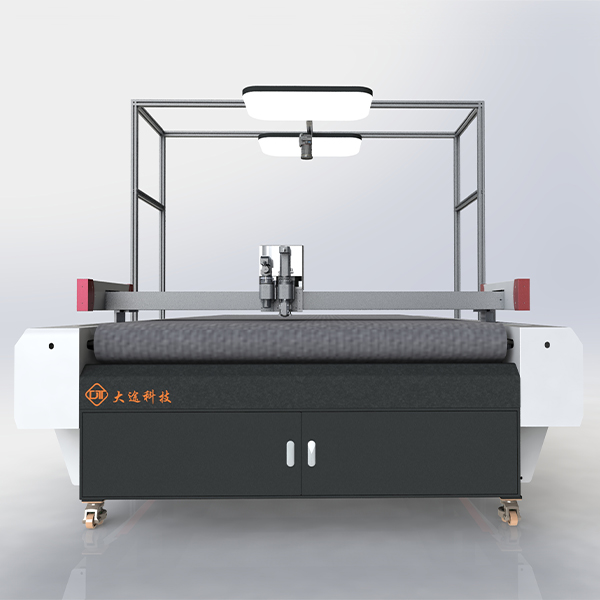

Equipment Model |

DT-2516A |

|

Scope Of Work |

2500x1600mm |

|

Drive System |

Imported Mitsubishi Servo Motor Drive |

|

Transmission System |

Pmi Linear Guide Rail, Precision Rack Drive |

|

Maximum Cutting Speed |

1800mm/s |

|

Cutting Material |

Microfiber, Genuine Leather, Regenerated Leather Etc. |

|

Cutting Tools |

Vibrating Knife, Round Knife Etc. |

|

Cutting Thickness |

0.1-30mm (Subject To Specific Materials) |

|

Cutting Accuracy |

±0.01mm |

|

Repetition Accuracy |

±0.03mm |

|

Feeding Method |

Automatic Feeding |

|

Fixing Method |

All Aluminum Table Vacuum Adsorption |

|

Transmission Interface |

Usb/u Disk/Network |

|

Power Supply And Power Of Cutting Equipment |

220v/50hz 2.5kw |

|

Power Supply And Power Of Vacuum Pump |

380v 7.5kw/9kw (Optional) |

|

Positioning Method |

Infrared Laser, Ccd Camera (Optional) |

|

Safety Device |

Infrared Laser Induction, Safe And Stable |

|

Pneumatic Fittings |

Festo, Germany/Yadek, Taiwan |

|

Electrical Fittings |

Chint/Delixi |

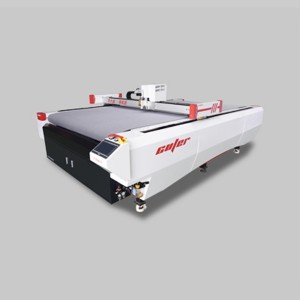

Datu Technology Vibration Knife has the characteristics of high efficiency and flexibility in leather bags and is a solution for various materials such as leather shoes, bags, haute couture leather goods, natural leather, artificial leather, and so on. From idea to finished product, from prototype to mass production, Datu Technology Vibrating Knife provides you with all-around technical support. Whether you are producing single batches or large batches, you can plan and process orders flexibly, making ad hoc order changes quickly and cost-effectively. It can help you better cope with the increased small batch production and customer inquiries for versioning and personalization.

1. The tool is modular, different tools are used with different materials, and the choice is flexible.

2. The intelligent cutting system can automatically identify material defects and take the initiative to avoid them.

3. Smart nesting material layout software, maximize the use of materials.

4. Digital cutting scheme, no need to make die, save cost.

5. Data import and direct cutting, no paper version is required. save time

6. High-speed punching function, punching, and sewing faster. save time.

7. Partition vacuum adsorption function, material fixation is more stable.

Applicable tools: vibrating kinfe, round knife

Applicable models: DT-2516A

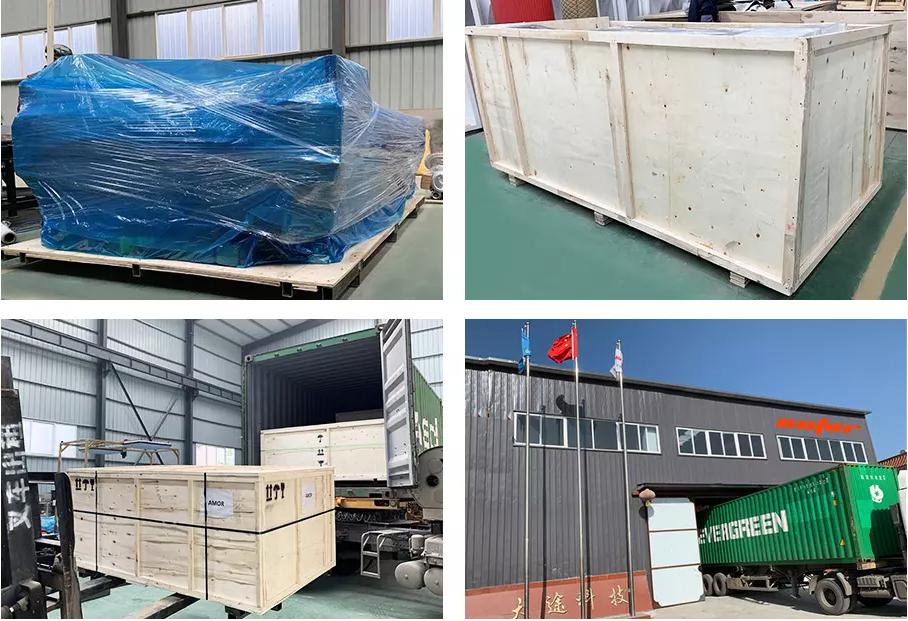

(1) One-year warranty policy.

(2) 7*24-hour online service.

(3) Provide lifetime free technology upgrade service.

(4) Free training in our factory, if time is not convenient, we can also provide complete training video.

(5) On-site technical support can be provided by negotiation.

We now have a specialist, efficiency workforce to deliver excellent service for our purchaser. We always follow the tenet of customer-oriented, details-focused for Supply ODM One-Way Particleboard Bent Wood Engraving Machine, Bent Wood Chair Back Cutting and Hole Drilling Machine Bent Wood Furniture Pressing and Shaping Machine, Honesty is our principle, skilled procedure is our perform, service is our target, and customers’ satisfaction is our long term!

We now have a specialist, efficiency workforce to deliver excellent service for our purchaser. We always follow the tenet of customer-oriented, details-focused for Supply ODM One-Way Particleboard Bent Wood Engraving Machine, Bent Wood Chair Back Cutting and Hole Drilling Machine Bent Wood Furniture Pressing and Shaping Machine, Honesty is our principle, skilled procedure is our perform, service is our target, and customers’ satisfaction is our long term!

Supply ODM China Oneway Particleboard Bent Wood Engraving Machine and Bent Wood Chair Back Cutting Hole Drilling Machi, Our company now has many department, and there have more than 20 employees in our company. We set up sales shop, show room, and product warehouse. In the meantime, we registered our own brand. We have tightened inspection for quality of product.

-

Wholesale Price China Kt Board Cutting CNC Knif...

-

Professional Factory for Asbestos/Cork/Nylon Ga...

-

Professional Design CNC Glass Cutting Machine f...

-

Excellent quality Car Floor Mats Seat Covers Cu...

-

High Quality for Realtop 2516 1825 Oscillating ...

-

OEM/ODM Manufacturer Green Products Acoustical ...