Bear “Customer initially, High-quality first” in mind, we work closely with our prospects and supply them with efficient and specialist companies for OEM Manufacturer Cardboard Cutting CNC Router 1325 1625 CNC Cutting Machine with Oscillating Knife, We’ve been self-confident that there will be considered a promising upcoming and we hope we could have long term cooperation with prospects from all over the environment.

Bear “Customer initially, High-quality first” in mind, we work closely with our prospects and supply them with efficient and specialist companies for China CNC Oscillating Knife Cutting Machine and Oscillating Knife, Our merchandise are mainly exported to Europe, Africa, America, the Middle East and Southeast Asia and other countries and regions. We now have enjoyed a great reputation among our customers for quality goods and good services.We would make friends with businessmen from at home and abroad, following the purpose of “Quality First, Reputation First, the Best Services.”

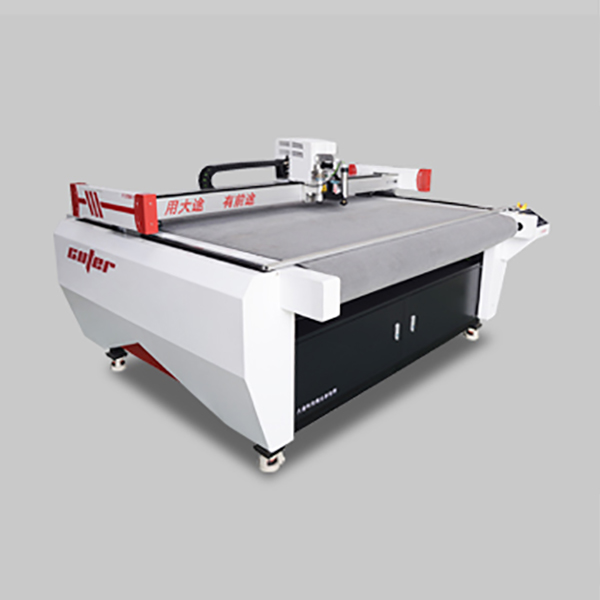

There are many non-metallic materials in sporting goods, including rubber, double-sided fleece, wool felt, high-strength carbon board, single-layer carbon fiberboard, multi-layer carbon fiberboard, PVC imitation leather, and microfiber, which are typical soft materials. Most of its cutting stays in traditional manual cutting or stamping. To achieve industrial transformation and the purpose of machine substitution, the introduction of advanced cutting.

In the application of flexible material cutting, the laser cutting machine has fast speed and high precision on thin materials that require high precision, but the processing speed is not fast for materials over 30mm, and will generate smoke and odor during the cutting process,and there will be burnt and blackened traces on the edge, which cannot meet the customer’s requirements, but the vibrating knife cutting machine can perfectly cut these flexible materials, with the same high speed, high precision, more flexible processing thickness, and more environmentally friendly.

|

Equipment Model |

DT-2516A |

|

Scope Of Work |

2500x1600mm |

|

Drive System |

Imported Mitsubishi Servo Motor Drive |

|

Transmission System |

Pmi Linear Guide Rail, Precision Rack Drive |

|

Maximum Cutting Speed |

1800mm/s |

|

Cutting Material |

Rubber, Wool Felt, High-Strength Carbon Board, Carbon Fiberboard, Pvc Imitation Leather, Microfiber Etc. |

|

Cutting Tools |

Vibrating Knife, Round Knife, Etc. |

|

Cutting Thickness |

0.1-30mm (Subject To Specific Materials) |

|

Cutting Accuracy |

±0.01mm |

|

Repetition Accuracy |

±0.03mm |

|

Feeding Method |

Automatic Feeding |

|

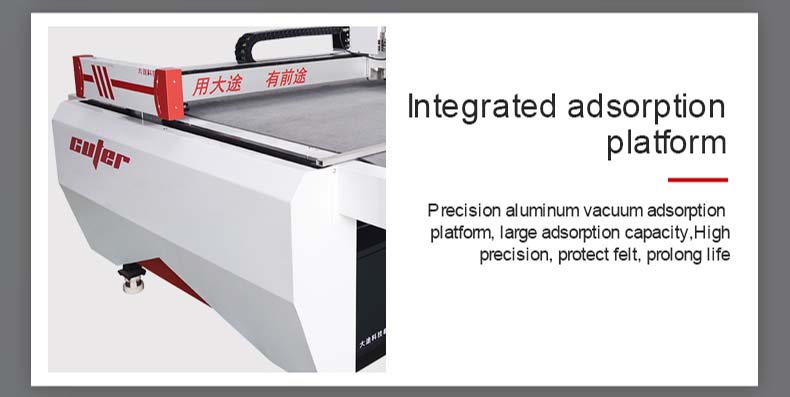

Fixing Method |

All Aluminum Table Vacuum Adsorption |

|

Transmission Interface |

Usb/u Disk/Network |

|

Power Supply And Power Of Cutting Equipment |

220v/50hz 2.5kw |

|

Power Supply And Power Of Vacuum Pump |

380v 7.5kw/9kw (Optional) |

|

Positioning Method |

Infrared Laser, Ccd Camera (Optional) |

|

Safety Device |

Infrared Laser Induction, Safe And Stable |

|

Pneumatic Fittings |

Festo, Germany/Yadek, Taiwan |

|

Electrical Fittings |

Chint/Delixi |

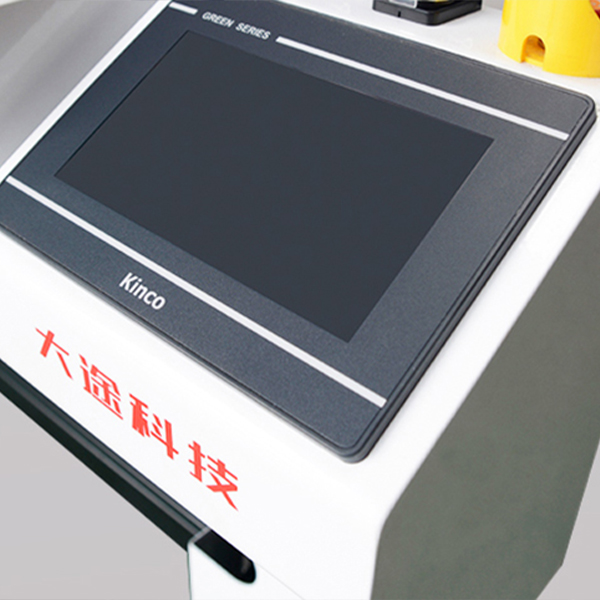

The Datu cutting system provides the best choice for multi-industry proofing and small batch production, equipped with various knives and pens to meet the cutting of multiple materials. It can achieve high-speed, high-intelligence, high-precision cutting, punching, drawing, and other processes. Using a powerful data conversion system, it can seamlessly connect with mainstream design software in the market, successfully realize the transition from manual production mode to high-speed and high-precision advanced production mode for customers, and fully meet customers’ personalized cutting needs.

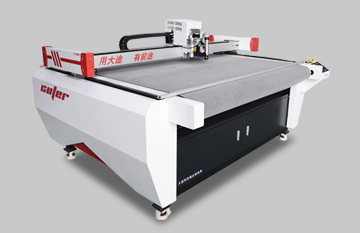

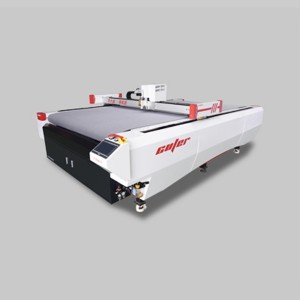

The high-speed large-format automatic cutting system independently developed and produced by Datu is a single-layer and a small number of multi-layer fixed-type cutting systems. It adopts an advanced motion control system and has the characteristics of fast running speed, high precision, and strong stability. The operation is simple; you only need to import the pattern file automatically and high-speed cutting (no proofing, line drawing, knife mold) carbon fiber, glass fiber, PVC, ETFE, PTFE, HYPALON, Oxford cloth, leather, and other flexible materials.

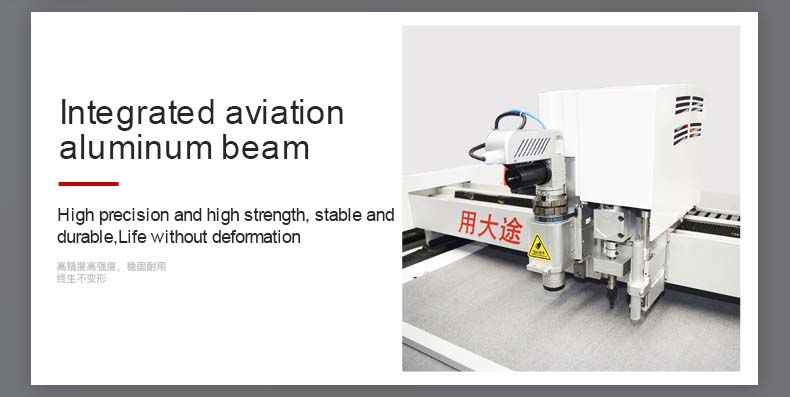

1. Special intelligent cutting system, integrated welding bed, stable and durable body;

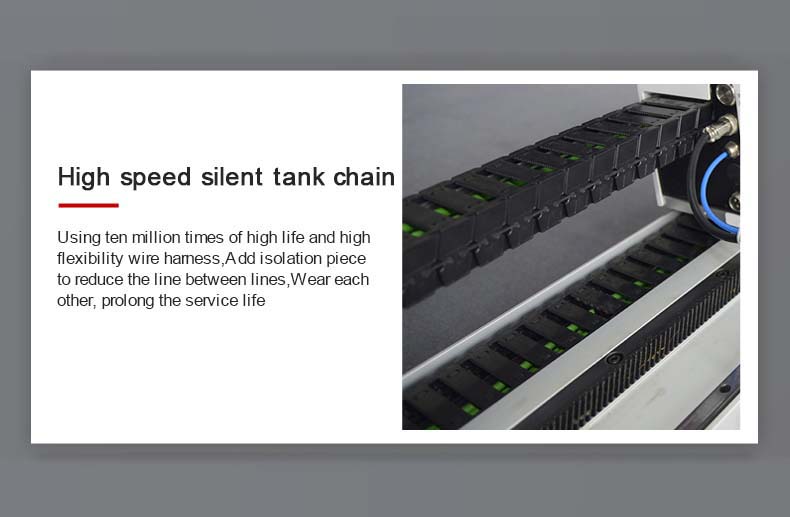

2. Adopt many first-line brand imported accessories to ensure accuracy and stability;

3. Support one-key import of drawings, automatic feeding, intelligent and simple operation;

4. Modular design is adopted to realize tool exchange, easy to use, and improve work efficiency;

5. Equipped with vibration knives, round knives, pneumatic knives, creasing knives, grooving knives, and other tools to meet the process requirements of special-shaped cutting, multi-angle grooving, punching, and strong indentation;

6. Intelligent safety protection system to ensure safety first.

Applicable Tools: Vibrating Knife, Round Knife, Pneumatic Knife

Applicable models: DT-2516A

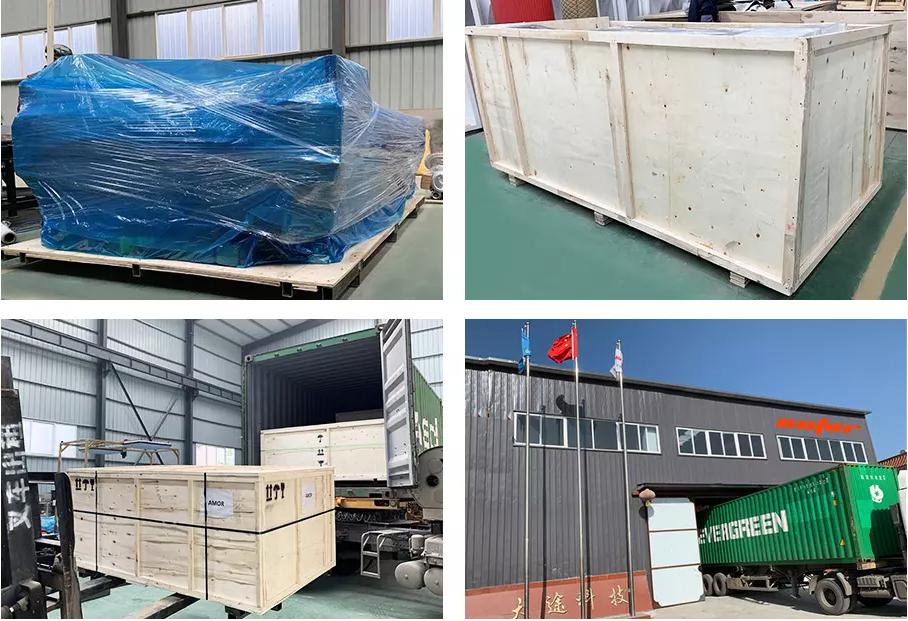

(1) One-year warranty policy.

(2) 7*24-hour online service.

(3) Provide lifetime free technology upgrade service.

(4) Free training in our factory, if time is not convenient, we can also provide complete training video.

(5) On-site technical support can be provided by negotiation.

Bear “Customer initially, High-quality first” in mind, we work closely with our prospects and supply them with efficient and specialist companies for OEM Manufacturer Cardboard Cutting CNC Router 1325 1625 CNC Cutting Machine with Oscillating Knife, We’ve been self-confident that there will be considered a promising upcoming and we hope we could have long term cooperation with prospects from all over the environment.

Bear “Customer initially, High-quality first” in mind, we work closely with our prospects and supply them with efficient and specialist companies for OEM Manufacturer Cardboard Cutting CNC Router 1325 1625 CNC Cutting Machine with Oscillating Knife, We’ve been self-confident that there will be considered a promising upcoming and we hope we could have long term cooperation with prospects from all over the environment.

OEM Manufacturer China CNC Oscillating Knife Cutting Machine and Oscillating Knife, Our merchandise are mainly exported to Europe, Africa, America, the Middle East and Southeast Asia and other countries and regions. We now have enjoyed a great reputation among our customers for quality goods and good services.We would make friends with businessmen from at home and abroad, following the purpose of “Quality First, Reputation First, the Best Services.”

-

Best Price on Automatic Die-Less CNC Cutting Ma...

-

Good Quality Digital Advertising Equipment Cutt...

-

ODM Factory Digital Accurate Clean Edge Cut by ...

-

China Cheap price 4axis 3D China Wood CNC Route...

-

Best Price for China Electric Fabric Rotary Cut...

-

Chinese Professional 1000W 2kw CNC Metal Fiber ...