Bear “Customer first, Excellent first” in mind, we operate closely with our customers and supply them with efficient and expert services for OEM China CNC Vertical/Horizontal Milling/Turret/Drilling/Boring Cutting CNC Machine/Machinery/CNC Machine, We feel you are going to be happy with our affordable selling price, top quality solutions and rapidly delivery. We sincerely hope you can give us an opportunity to provide you and be your best partner!

Bear “Customer first, Excellent first” in mind, we operate closely with our customers and supply them with efficient and expert services for China CNC Machine and CNC, Based on our guiding principle of quality is the key to development, we continually strive to exceed our customers’ expectations. As such, we sincerely invite all interested companies to contact us for future cooperation, We welcome old and new customers to hold hands together for exploring and developing; For more information, please feel free to contact us. Thanks. Advanced equipment, strict quality control, customer-orientation service, initiative summary and improvement of defects and extensive industry experience enable us to guarantee more customer satisfaction and reputation which, in return, brings us more orders and benefits. If you are interested in any of our products and solutions, make sure you feel free to contact us. Inquiry or visit to our company are warmly welcome. We sincerely hope to start a win-win and friendly partnership with you. You can see more details in our website.

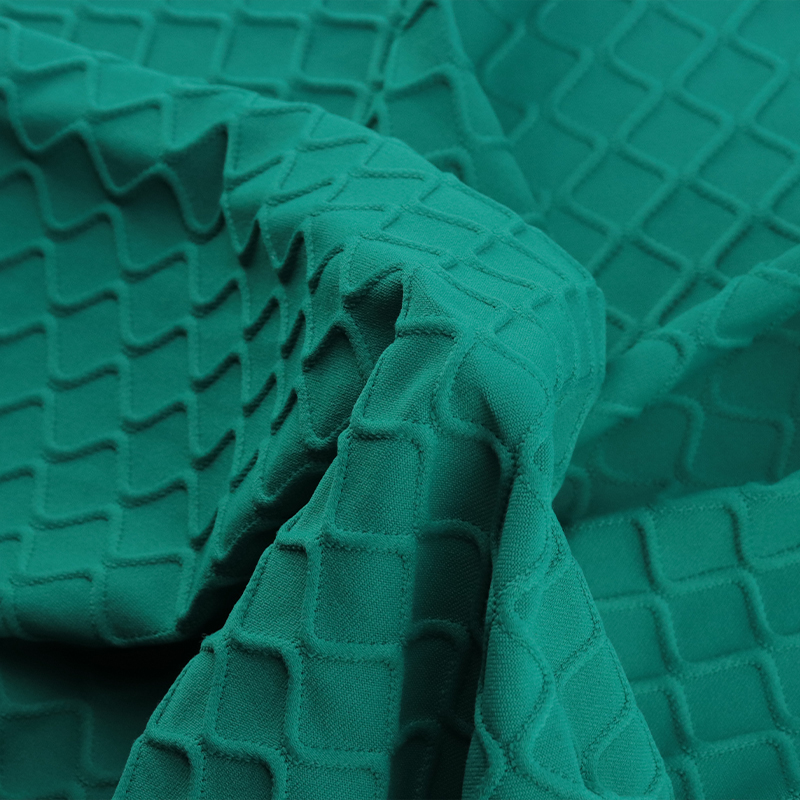

Clothing is made of various fabrics, such as cotton, linen, silk, woolen, leather, chemical fiber, blended, yarn-dyed, knitted, etc., which are typical soft materials. Design and production methods are changing to meet the needs of the market economy and global economic development. “Multi-variety, small-batch, high-quality, fast-paced” and the transformation and upgrading from OEM to ODM are inevitable trends in the development of the apparel industry.

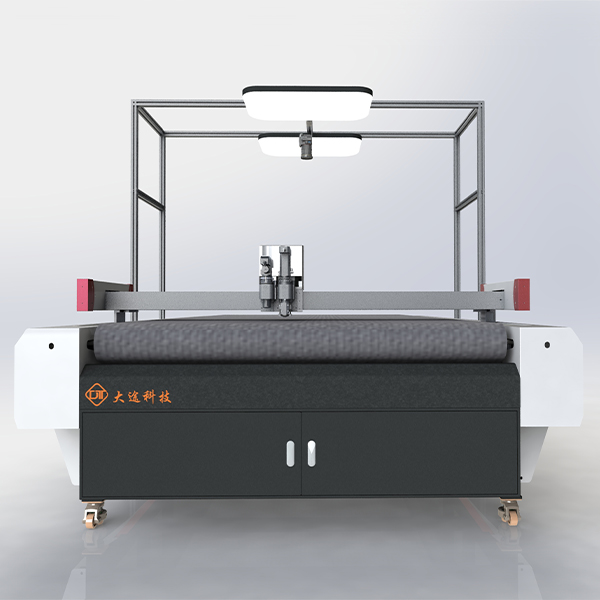

Digital vibrating knife cutting machine for the textile and apparel uses the power on the machine arm and the high-speed rotation of the blade to make the cutting. the finished product is exquisite and beautiful, the incision is smooth and clean, the efficiency is improved, and the cost is reduced. it is not only suitable for fur cutting, but also for various clothing fabrics such as: woven fabrics, chemical fiber fabrics, babes, plain cloth, muslin, plush, etc. can also be cut.

1. Look at the appearance. Small details such as the distance between the round blade and the bottom surface, the shape and size of the blade, and the design of the machine tool panel will all have an impact on the cut samples.

2. Depending on the smoothness of the finished product, the finished product cut and cut by the circular knife must be clean and neat, with smooth and flawless edges.

3. Look at the voltage, power, speed and other points, which is also an intuitive feeling that reflects the quality of a machine.

4. Continuity of work. A qualified round knife cutting must be equipped with imported servo motors and high-precision rotary knives, which can work stably and quickly in cutting materials continuously.

|

Equipment Model |

DT-2516A /DT3520A |

|

Scope Of Work |

2500x1600mm/3500×2000mm |

|

Drive System |

Imported Mitsubishi Servo Motor Drive |

|

Transmission System |

Pmi Linear Guide Rail, Precision Rack Drive |

|

Maximum Cutting Speed |

1800mm/s |

|

Cutting Material |

Cotton, Linen, Silk, Woolen, Leather,Blended, Yarn-Dyed, Knitted, Etc. |

|

Cutting Tools |

Vibrating Knife, Round Knife Etc. |

|

Cutting Thickness |

0.1-30mm (Subject To Specific Materials) |

|

Cutting Accuracy |

±0.01mm |

|

Repetition Accuracy |

±0.03mm |

|

Feeding Method |

Automatic Feeding |

|

Fixing Method |

All Aluminum Table Vacuum Adsorption |

|

Transmission Interface |

Usb/u Disk/Network |

|

Power Supply And Power Of Cutting Equipment |

220v/50hz 2.5kw |

|

Power Supply And Power Of Vacuum Pump |

380v 7.5kw/9kw (Optional) |

|

Positioning Method |

Infrared Laser, Ccd Camera (Optional) |

|

Safety Device |

Infrared Laser Induction, Safe And Stable |

|

Pneumatic Fittings |

Festo, Germany/Yadek, Taiwan |

|

Electrical Fittings |

Chint/Delixi |

Datu Technology provides professional solutions for the textile and garment industry. We adopt corresponding cutting solutions according to different types of fabrics, such as cotton, linen, silk, woolen, leather, chemical fiber, blended, yarn-dyed, knitted, etc. The digital production method can quickly provide samples for personalized style requirements, saving time and costs. Provide a full range of technical services from R&D to production for small batch production. Whether you are producing single batch or large batches, you can plan and process your orders flexibly, making ad-hoc order changes quickly and cost-effectively. It can help you better cope with the increased small batch production and customer inquiries for versioning and personalization.

1. The tool is modular, different materials are used with different tools, and the choice is flexible.

2.1800MM/S high speed, 0.01MM repeated positioning accuracy.

3. Mitsubishi servo motors, Taiwan Hindwin guide rails and other brand electrical components, double rack machines are more durable

4. There are more cutting configurations for the round knife, vibrating knife, and pneumatic knife cutter.

5. Equipped with a large visual intelligent edge inspection system, cutting and proofing are faster.

6. Support for multiple file formats (AI, PLT, DXF, CDR, etc.), making it more convenient to use and interact with.

7. Fully automatic feeding device, saving the trouble of manual handling

8. Multi-material shelves, realize flexible switching of various materials and automatic feeding of multi-layer materials

9. Automatic material receiving device to realize the solution that the material does not fall to the ground

Applicable tools: vibrating kinfe, round knife

Applicable models: DT-2516A DT-3520A

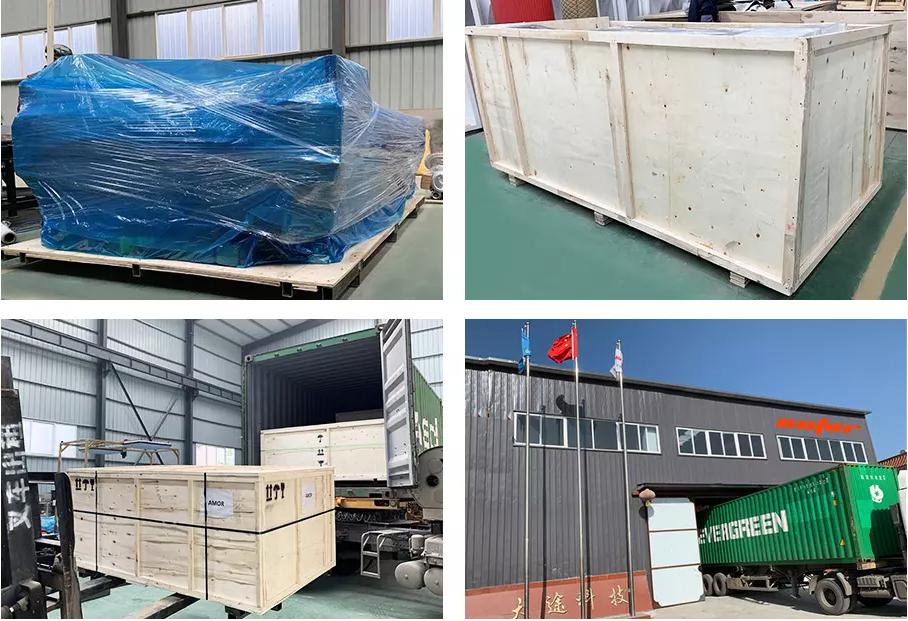

(1) One-year warranty policy.

(2) 7*24-hour online service.

(3) Provide lifetime free technology upgrade service.

(4) Free training in our factory, if time is not convenient, we can also provide complete training video.

(5) On-site technical support can be provided by negotiation.

Bear “Customer first, Excellent first” in mind, we operate closely with our customers and supply them with efficient and expert services for OEM China CNC Vertical/Horizontal Milling/Turret/Drilling/Boring Cutting CNC Machine/Machinery/CNC Machine, We feel you are going to be happy with our affordable selling price, top quality solutions and rapidly delivery. We sincerely hope you can give us an opportunity to provide you and be your best partner!

OEM China China CNC Machine and CNC, Based on our guiding principle of quality is the key to development, we continually strive to exceed our customers’ expectations. As such, we sincerely invite all interested companies to contact us for future cooperation, We welcome old and new customers to hold hands together for exploring and developing; For more information, please feel free to contact us. Thanks. Advanced equipment, strict quality control, customer-orientation service, initiative summary and improvement of defects and extensive industry experience enable us to guarantee more customer satisfaction and reputation which, in return, brings us more orders and benefits. If you are interested in any of our products and solutions, make sure you feel free to contact us. Inquiry or visit to our company are warmly welcome. We sincerely hope to start a win-win and friendly partnership with you. You can see more details in our website.

-

OEM/ODM Factory Automatic Aluminum Window Door ...

-

2019 Good Quality 1625 Oscillating Knife Automa...

-

New Arrival China Full Automatic Paper Roll to ...

-

Newly Arrival China Shoes Material Cutting Mach...

-

Factory Customized Digital CNC Cutting Machine ...

-

100% Original Factory 100W CO2 Fabric Laser Eng...