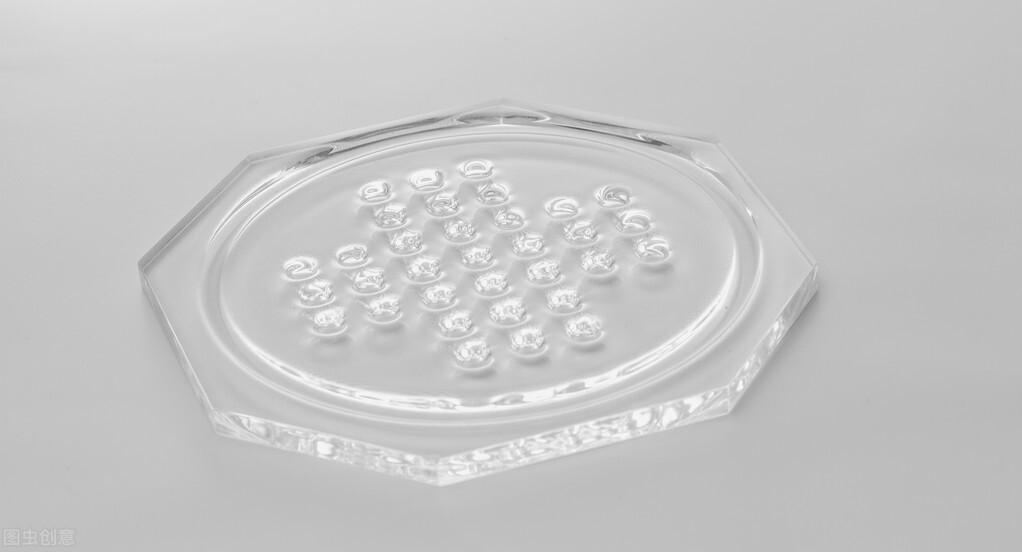

Acrylic, also known as PMMA, is an important plastic polymer material developed earlier. It has good transparency, chemical stability, easy dyeing, easy processing, and beautiful appearance. It has a wide range of applications in all walks of life.

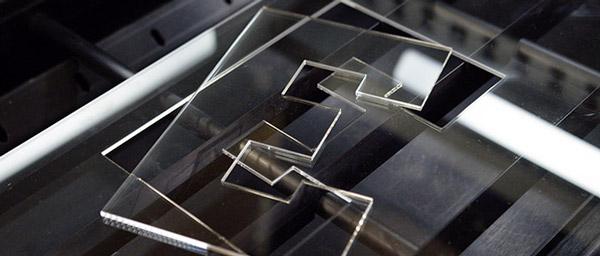

Acrylic cutting methods include laser cutting, manual knife cutting and vibrating knife cutting.

Manual knife cutting is mainly manual cutting with a blade or a chainsaw. Manually cutting acrylic boards requires planning the board in advance, and then cutting it with a hook knife or a chainsaw according to the pattern. If you want a neat edge, you can polish it. The characteristics are that the cutting is difficult, the precision is poor, and the safety of use is low. If you use a chainsaw to cut, it will cause the acrylic to melt, which will have a certain impact on the beauty of the cut product.

Both the vibrating knife cutting machine and the laser cutting machine use machine cutting. Its cutting acrylic process is:

1. Typesetting software automatically typeset

2. Place the material on the work surface

3. The machine starts cutting

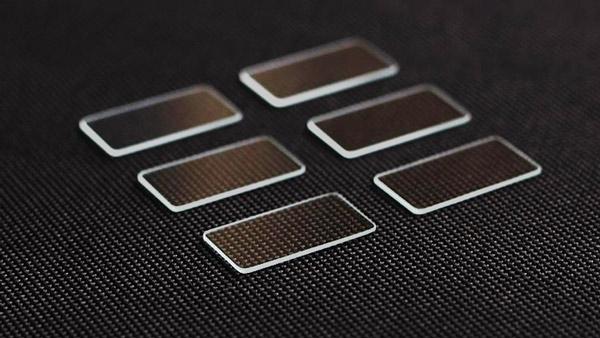

The laser machine is a thermal cutting method, which will generate a lot of smoke and unpleasant smell during the cutting process, and the environmental protection problem is serious. Moreover, high temperature cutting will produce the phenomenon of burnt edge and black edge, which especially affects the cutting effect and also affects the quality of the product.

The vibrating knife cutting has the characteristics of environmental protection and no smoke and dust, and can be replaced with different cutter heads, round knives, punching knives, oblique knives, etc. The machine is operated by computer, and the intelligent typesetting software is used for typesetting, which can improve the utilization rate of materials by more than 90%. It not only saves material, but also saves labor and improves the safety of operation.

Post time: Sep-20-2022