Computer cutting machine also known as the vibrating knife cutting machine, the length of the equipment is about 3100mm, the width is about 2100mm, the workbench area is 1600mm*2500mm, of course, the area of the workbench is to support customization, the computer cutting machine generally uses the pulse positioning system, the positioning accuracy is generally ±0.01mm.

I will tell you the factors that affect the accuracy of the computer cutting machine from four aspects.

The first thing that affects the accuracy is the positioning accuracy of the driver, which is also the basis of the cutting accuracy, if there is no such condition, the equipment is no good, and the general drive and motor choose Mitsubishi.

The second impact of the computer cutting machine error is the elasticity of the material, fabric, imitation fur class elasticity is larger, such materials even if the equipment is adjusted to the best state, and start the automatic error compensation system of the equipment, its cutting accuracy is about 5mm. If the ductility of materials such as electronic film materials is poor, the cutting error of the computer cutting machine can be within ±0.05mm.

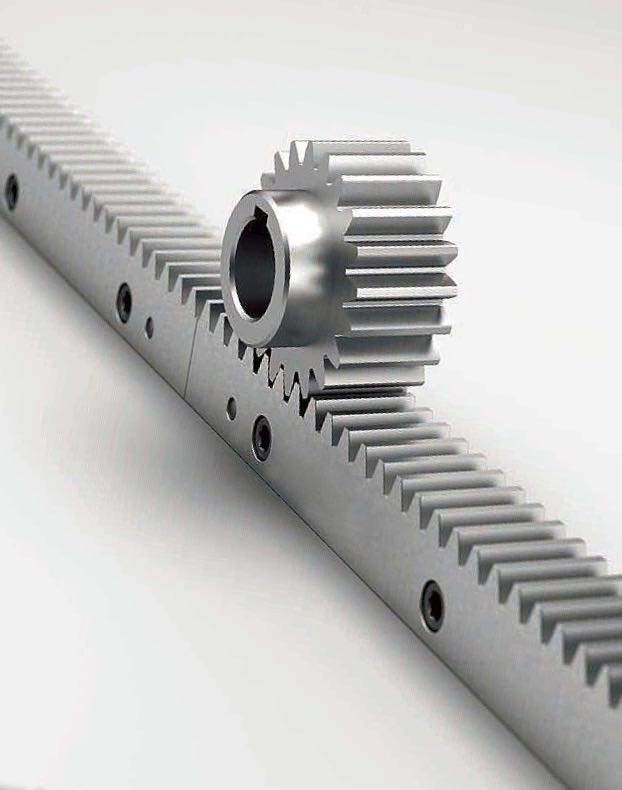

Third, the guide rail accuracy of the equipment directly affects the cutting accuracy of the material, and the fit of the guide gear is an important factor affecting the material accuracy, and the helical gear should be used to reduce the gap in the middle.

Fourth equipment stability, equipment adjustment is also an important factor of equipment cutting accuracy, most manufacturers do not pay attention to the standardization of equipment and accessories, the result of equipment production accuracy is very poor, we can set the standardization of equipment at the time of equipment production, so that the production of equipment is unified.

Post time: Nov-28-2023