To make a surfboard, you need to use polystyrene foam board, extruded polystyrene foam board or polyurethane foam board, and glass fiber. In this article we tell about the content of surfboard cutting machine.

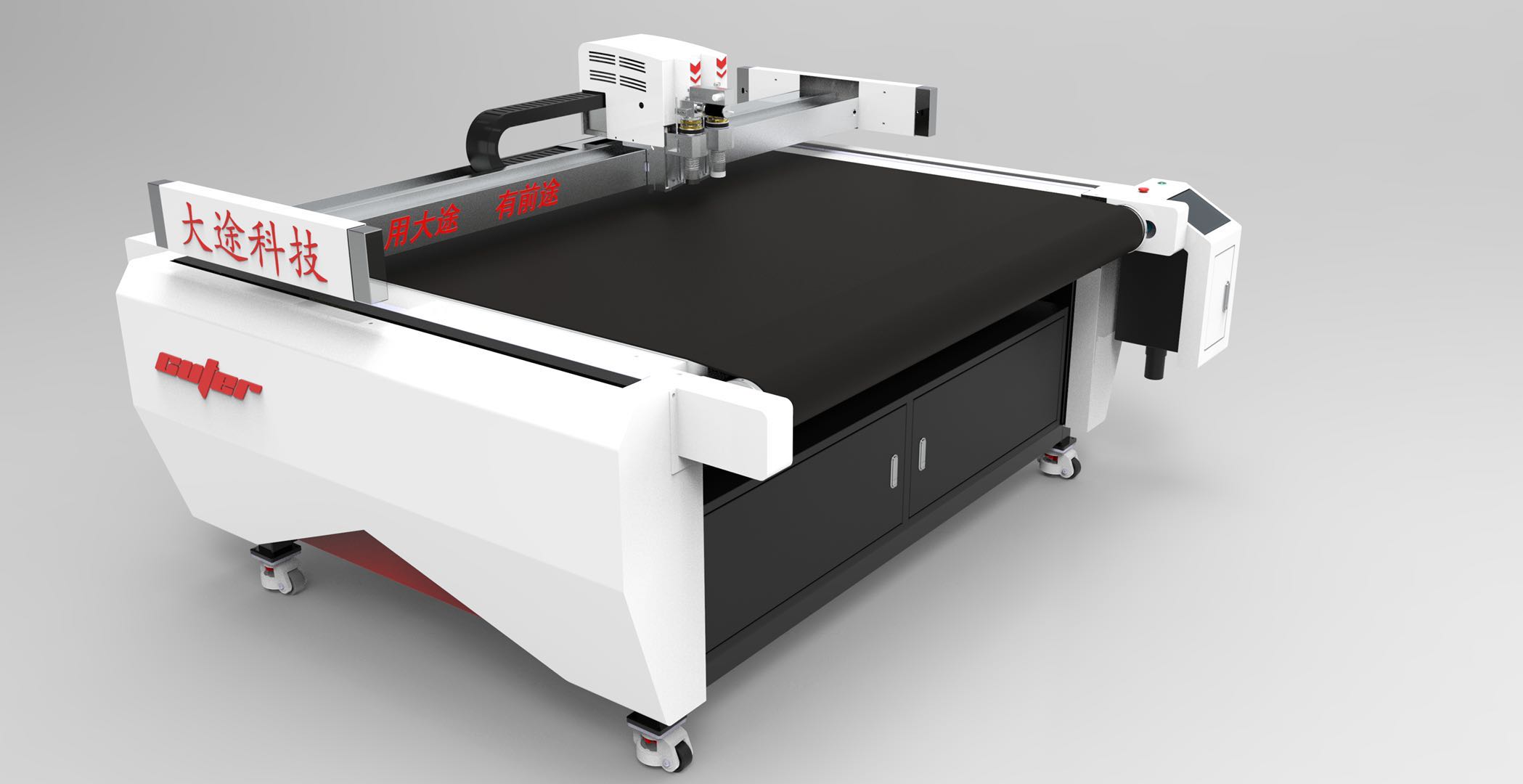

Surfboard cutting machine supports the cutting of all the above materials, the equipment is controlled by computer, with the control panel and the tool to achieve the purpose of cutting.A wide range of cutting tools, with vibration knives, milling knives, pneumatic knives, round knives, grooving, punching, etc., respectively to deal with different materials of different processes.

For polystyrene foam board, extruded polystyrene foam board or polyurethane foam board materials use a pneumatic knife or a milling cutter, the pneumatic knife is for the thickness and hardness of the high material for cutting, milling cutter is for the material is very hard material support slotting, cutting. For cutting glass fiber cloth, it is recommended to use a round knife or a vibrating knife. The round knife is suitable for materials with better permeability, and the vibrating knife is suitable for slightly thinner materials that are not breathable.

Surfboard cutting machine Advantages:

Advantage 1: High efficiency, the equipment independently developed cutting system, with multi-axis control, cutting speed up to 2000mm/s, of course, the cutting speed is affected by the hardness and thickness of the material, the general cutting interval between 200-1200mm/s.

Advantage 2: high accuracy, although the accuracy of the cutting effect of glass fiber cloth is not large, but for the cutting accuracy of polystyrene foam board, extruded polystyrene foam board or polyurethane foam board is higher, the accuracy of this equipment can be up to ±0.01mm.

Advantage 3: Material saving, the material saving of this device is achieved by the computer typesetting system, for some fixed graphics typesetting, equipment typesetting compared with manual typesetting can save more than 15% of materials

Post time: Aug-01-2023