With the continuous development of science and technology, our sports methods have become diverse, and sporting goods are constantly being updated. Most of our common sporting goods are obtained by using carbon fiber materials to synthesize high-density materials through high-temperature pressure, or using glass fibers as reinforcing materials to be pressurized and solidified. Sporting goods often require impact resistance and good toughness, while carbon fiber is a special fiber composed of carbon elements, which has the characteristics of anti-friction, corrosion resistance, impact resistance, and high strength, so it is mostly used in aerospace, sporting goods, etc.

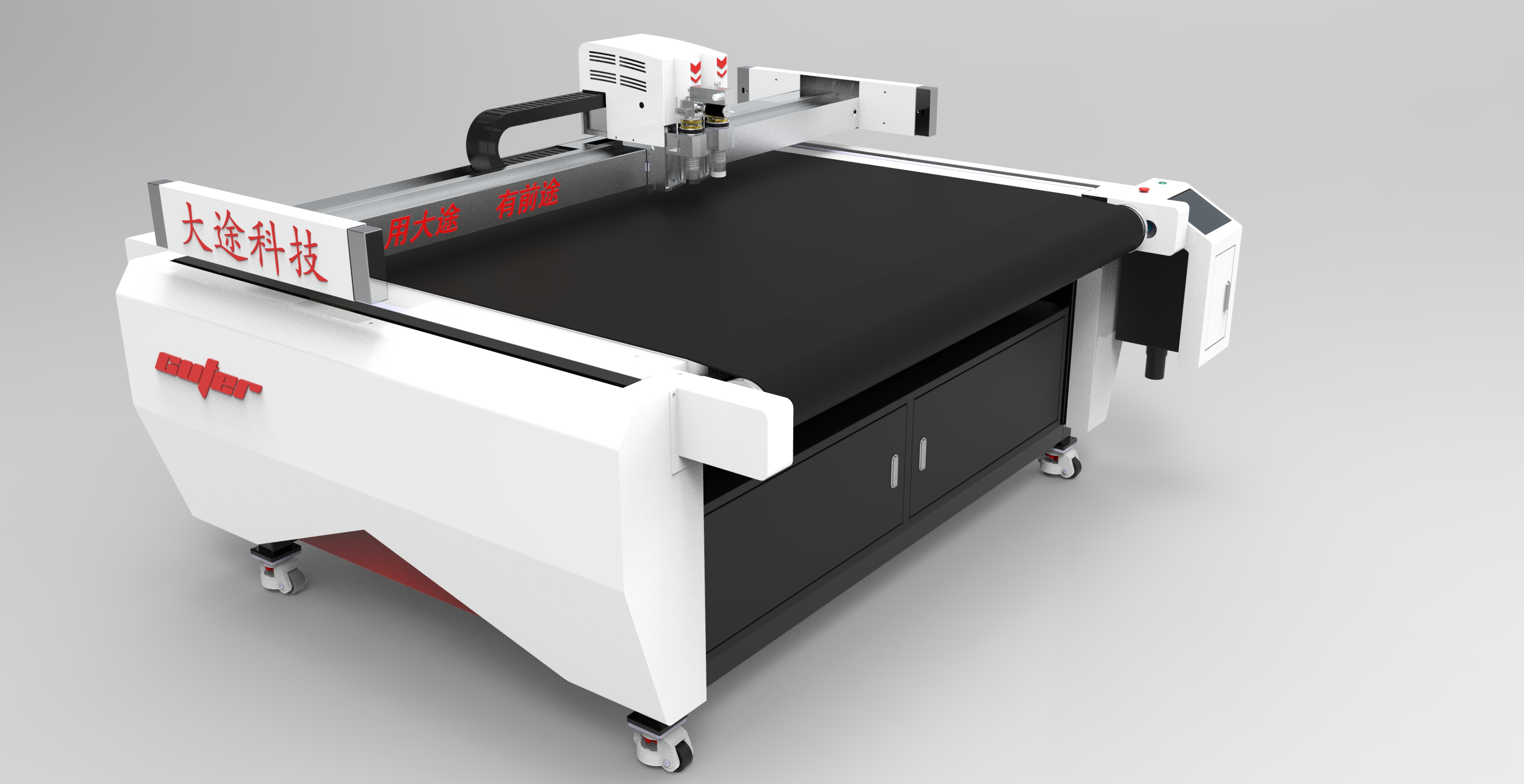

Due to the high strength and impact resistance of the material itself, the cutting requirements are relatively high, and ordinary labor and molds cannot meet the required cutting requirements. How to solve these problems, let’s take a look at Datu’s vibrating knife cutting machine.

The vibrating knife cutting machine adopts blade cutting, which is environmentally friendly and has no peculiar smell, and does not change the characteristics of the material. The equipment adopts an intelligent cutting system, automatic feeding, automatic typesetting, one-key cutting, saving time and effort. The super material-saving software independently developed by Datu has increased the utilization rate of materials by more than 15% compared with manual cutting.

Post time: Apr-13-2023