With the development of the current society, the dependence on manual is becoming less and less, and digitization is the trend of the future. For some industries, although they can not fully enter the digital production, they also gradually reduce the dependence on manual. Today we will talk about the processing of shoes.

Traditional shoe processing needs to use punch or manual sample cutting, the leather can be cut into sewing shoe pieces, and then assembly, punch cutting needs mold manufacturing, this cost is very high, small batch production of a single mold cost can increase the cost of shoes by more than 10%, which is very unfavorable to market competition. Moreover, there will be a certain period of mold production, which will cause low production efficiency. Manual cutting is the same, high labor costs, and because of manual error caused by the waste of material costs are very high, in order to solve this problem, Datu developed the shoe upper cutting machine.

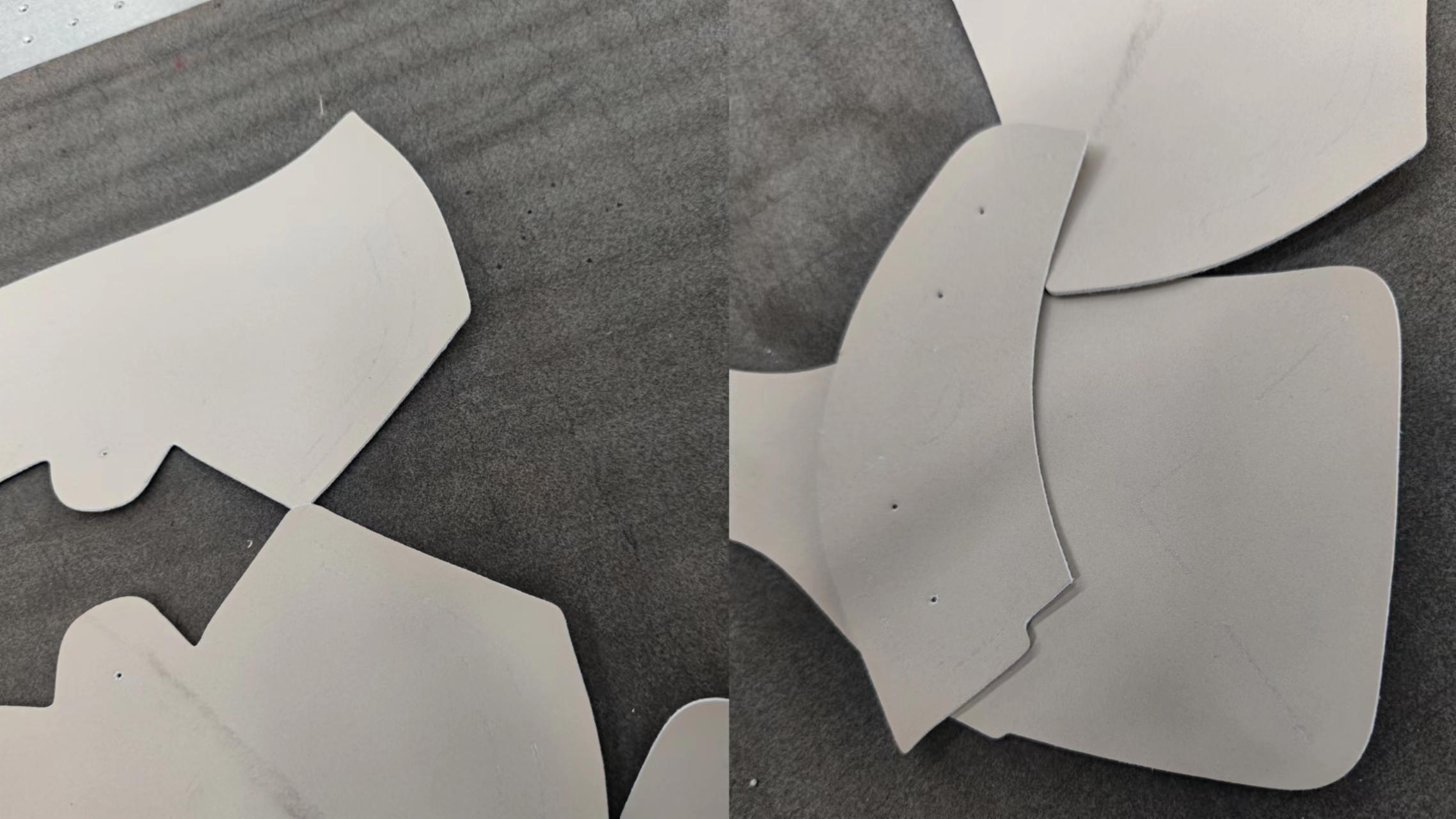

Upper cutting machine is computer controlled, data cutting, the leather material needs to be placed in the feeding rack, the computer design publication type, automatic typesetting can output cutting, the operation is very simple, and the cutting precision is high, save materials. The equipment also has a leather identification system, which can automatically avoid defects, automatic typesetting, and can calculate the utilization rate of materials, so that the production can be digitized.

Shoe upper cutting machine is not only suitable for leather,but also suitable for fabric, EVA soles, mesh cloth and other materials, a multi-purpose machine, a device to solve all the cutting process of the whole shoe.

The shoe upper cutting machine has been maturely applied to the shoe processing factory and has been trusted by the manufacturer. At present, the equipment can be connected to the assembly line, which greatly improves the production efficiency of the manufacturer and promotes the digital production process of the manufacturer.

Post time: Nov-21-2022