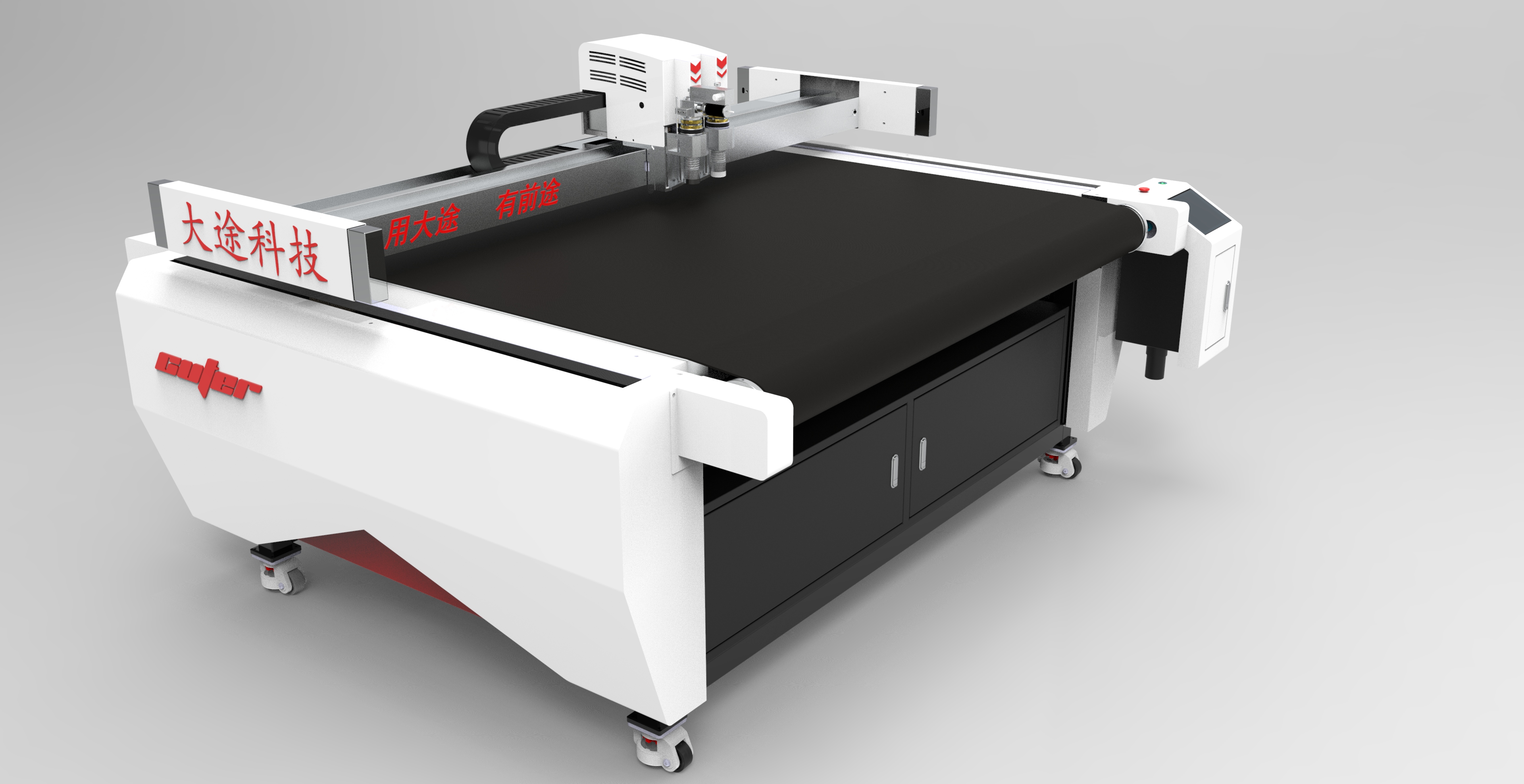

PVC foam board cutting machine, also known as vibrating knife cutting machine, has a variety of cutting heads, common ones include vibrating knife, pneumatic knife, round knife, etc. The equipment adopts computer cutting, high cutting precision, no need for molds, and is suitable for cutting various materials.

The body of the equipment is welded with a wall thickness of 6mm. It ensure that the equipment does not deform during long-term use. The weight of the whole machine is as high as 1.5t, ensuring that the equipment is no shake during high-speed operation to ensure the cutting accuracy of the equipment.

Advantages of PVC foam board cutting machine:

1. The cutting precision is high. The equipment adopts the pulse positioning system, and the positioning precision is ±0.01mm. The cutting precision needs to change according to the change of the material elasticity, and the highest can be 0.01mm.

2. The cutting efficiency is high, the equipment adopts imported servo system, and is equipped with the self-developed cutting system, and the operating speed can reach 2000mm/s.

3. Saving materials. The equipment has an automatic typesetting system. Compared with manual typesetting, equipment typesetting can save more than 15% of materials.

4. Environmental protection, the equipment adopts blade cutting, no smoke, no peculiar smell, and meets the national environmental protection requirements.

Post time: Feb-17-2023