The emergence of graphene film solves the problem that superconducting materials and flexible materials cannot be balanced. Graphene material is a high-quality superconducting material. Its conduction speed is faster than copper and aluminum, its thermal resistance is low, and its weight is light. It is widely used in electronic products.

The characteristics of graphene film materials are also factors that determine the cost of materials. We can provide intelligent graphene film cutting machines to help manufacturers reduce production costs and improve production efficiency.

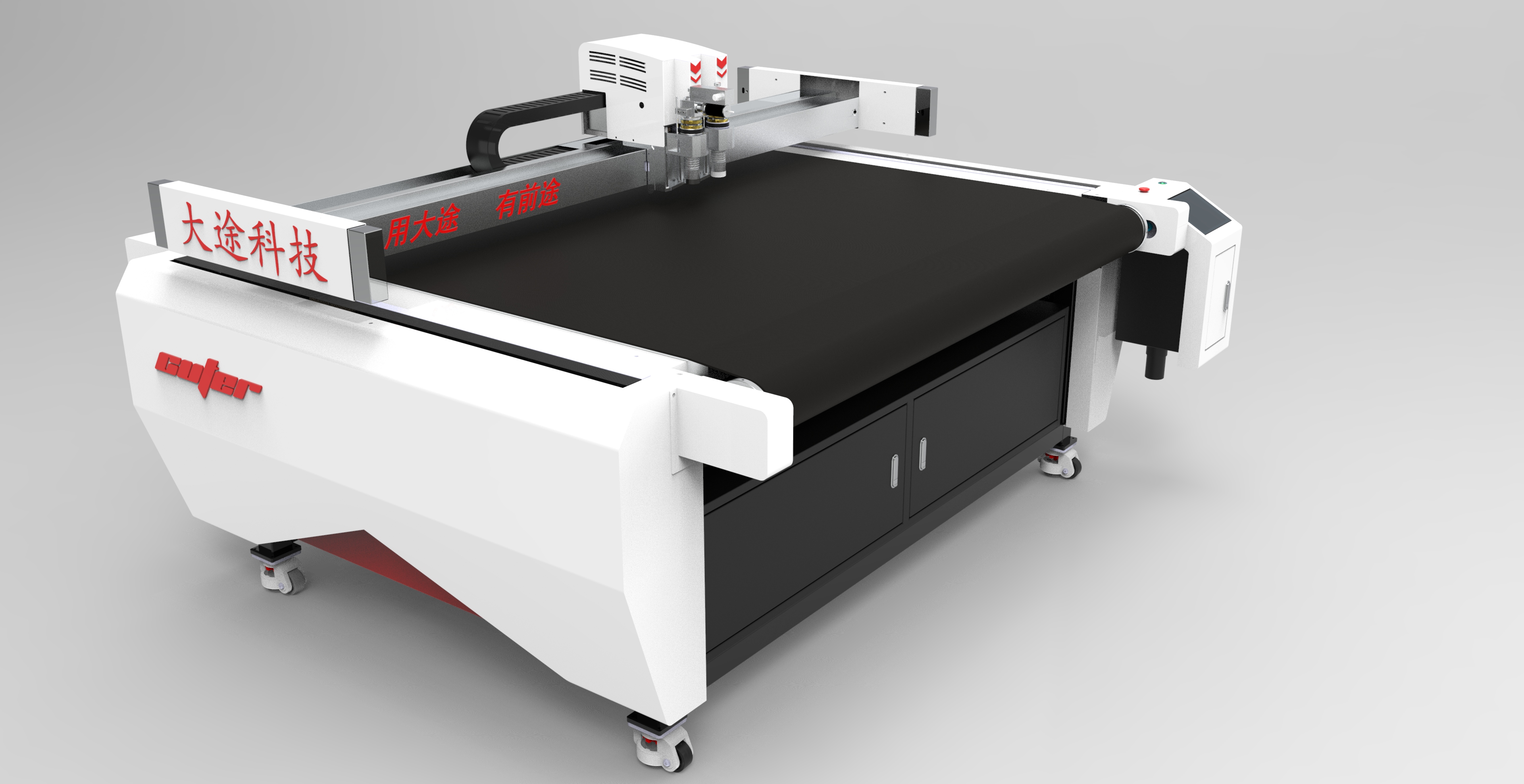

Graphene film cutting machine, also known as vibrating knife cutting machine, adopts computer-controlled data cutting, no mold is needed, and the whole machine adopts an integrated welding process, the equipment can be used for a long time without deformation. The working table is made of aviation alloy material, and it is equipped with a vacuum sub-area fixing system to firmly fix the material on the working surface to ensure the cutting accuracy of the material.

Advantages of graphene film cutting machine:

1. High cutting accuracy, equipment positioning accuracy is ±0.01mm, cutting accuracy is ±0.01mm.

2. The cutting speed is high, and the operating speed of the equipment is 2000mm/s. The cutting speed is inversely proportional to the hardness and thickness of the material. For the specific cutting speed, please consult the online personnel.

3. Save material, the equipment adopts data typesetting and cutting, compared with manual typesetting, the material typesetting of equipment saves more than 15%.

Post time: Feb-06-2023