The clothing market is basically saturated now, the market competition is very large, and it is difficult to draw a distance between the major manufacturers in terms of clothing appearance and fabrics. The only thing that can improve the competitiveness of products is the cutting quality and cutting speed of the fabric.

Nowadays, many garment manufacturers are still using manual cutting. The efficiency of manual cutting is too low, and the accuracy cannot be completely guaranteed. Secondly, the difficulty of manual cutting and recruiting has become a headache for many manufacturers. The wages of skilled workers will be very high, which is another very large expense.

In recent years, the flexible material cutting industry has gradually developed in the direction of intelligence and automation, and the fabric cutting equipment has also been updated quickly. From laser machines to vibrating knives, the cutting speed is getting faster and faster, and the cutting effect is getting better and better.

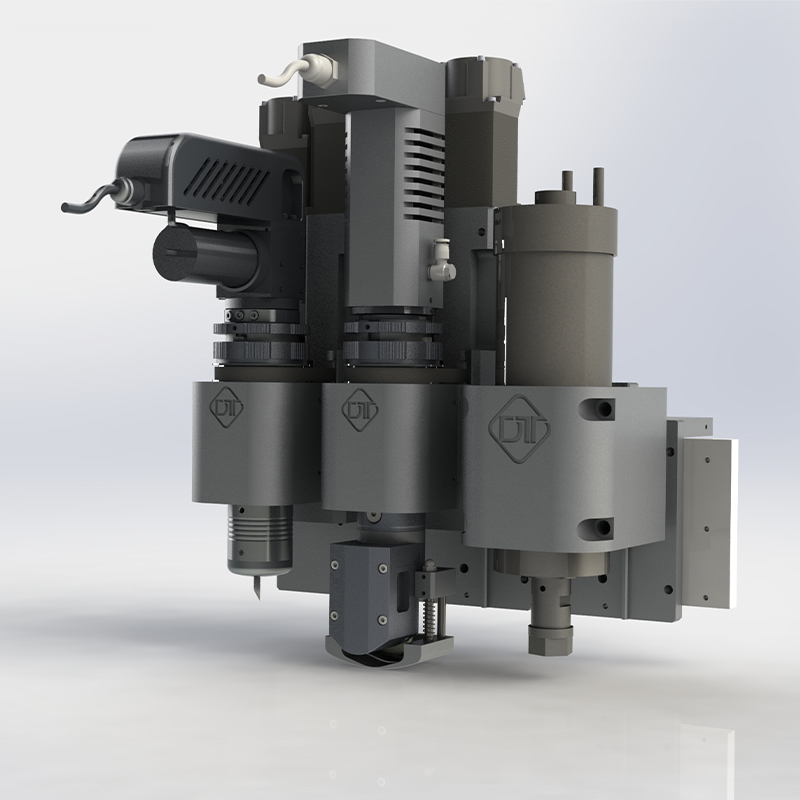

The circular knife cutting machine for clothing fabrics is specially developed for fabric cutting. This equipment has the advantages of high processing accuracy, fast speed, no peculiar smell, green environmental protection, and intelligence. It has been widely used in textile, leather, fiber and other clothing processing fields, and has achieved good results.

The clothing fabric cutting machine adopts a circular knife head, which uses the high-speed rotation of the blade to cut the material. With the addition of imported servo motors, the cutting precision is higher and the speed is faster, which is 5-8 times of manual cutting, and can work 24 hours continuously, further improve production efficiency.

In terms of typesetting, manual board making is time-consuming and laborious.Datu vibrating knife cutting equipment has an automatic typesetting system, which saves manpower and saves time. It also perfectly solves the problem of material waste caused by inappropriate manual typesetting.

The multi-axis control system can realize the special-shaped cutting of materials, and the CCD recognition system can identify the patterns on the materials, and automatically generate the cutting path, so that the cutting is more intelligent and efficient.

Post time: Oct-09-2022