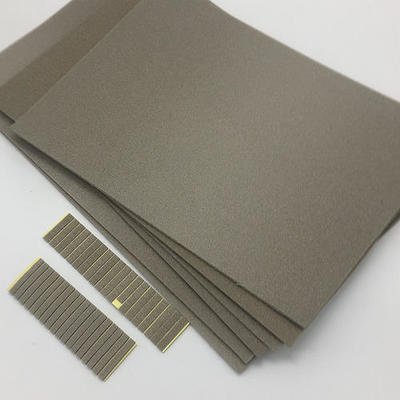

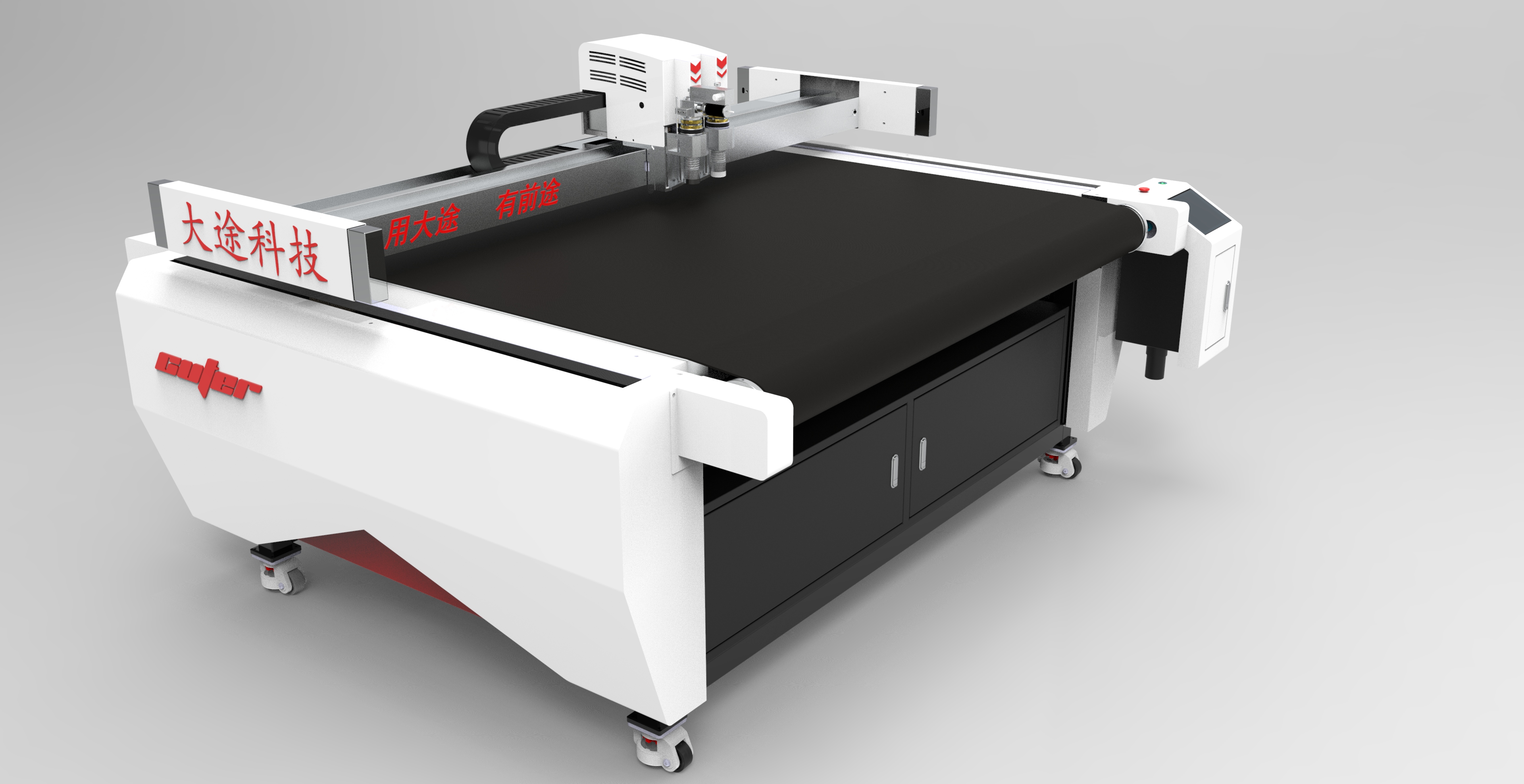

Conductive cotton cutting machine is also known as vibrating knife cutting machine. The cutting method is blade cutting, controlled by computer, and cutting by using the up and down vibration of the blade. The conductive cotton cutting machine integrates feeding, cutting and unloading, and provides customized conductive cotton cutting solutions to help manufacturers reduce costs and increase efficiency, and promote digital development.

The overall cutting process is:

1. Computer drawing, the computer designs the shape to be cut, and starts the automatic typesetting function.

2. Import the pattern into the equipment, and place the conductive cotton coil behind the equipment.

3. Adjust equipment parameters, speed, cutting depth, etc., and start cutting with one key.

4. The equipment starts cutting, and automatically unloads the material after cutting.

Advantages of conductive cotton cutting machine:

Advantage 1: High precision, the equipment adopts pulse positioning, the positioning accuracy is ±0.01mm, and the cutting accuracy also needs to consider the elastic change of the material, and the maximum precision can be ±0.01mm.

Advantage 2: The cutting speed is fast. The equipment adopts the self-developed cutting system and Mitsubishi servo system, and the operating speed can reach 2000mm/s.

Advantage 3: Saving material . The equipment comes with a computer typesetting system. Compared with manual typesetting, equipment typesetting can save more than 15% of materials.

Post time: Mar-08-2023