-

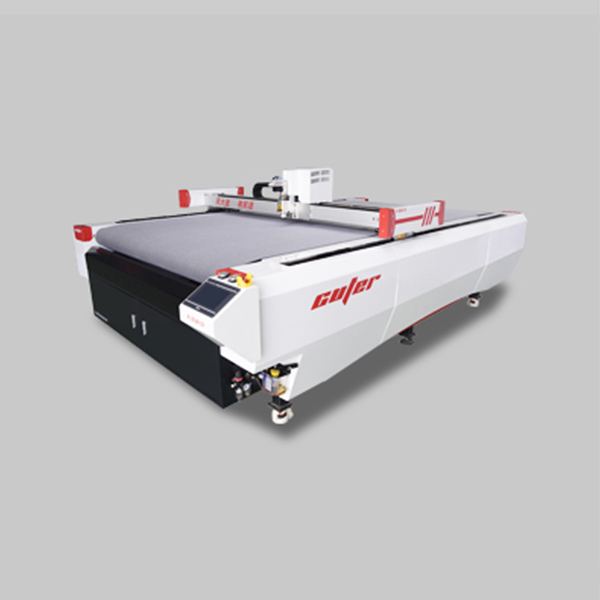

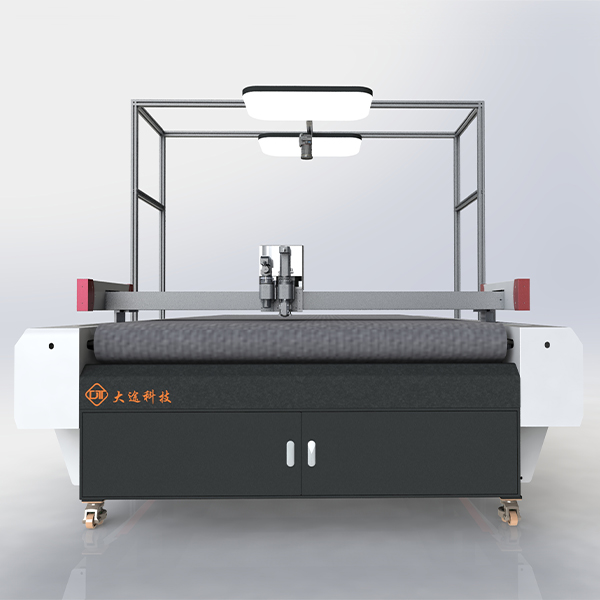

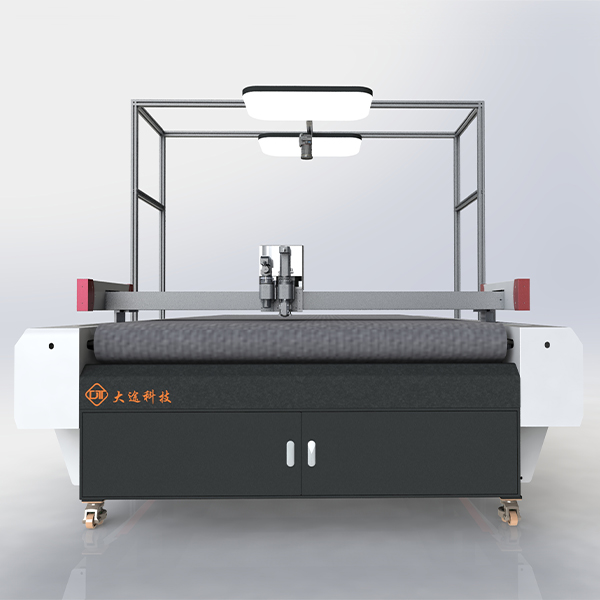

Leading Manufacturer for High Quality CNC Router Sponge Foam Rubber Leather Fabric Vibration Knife Cutting Machine

Due to the particularity and easy deformation of composite materials, the material cost is high. At the same time, considering that the data of the material pieces are mostly special-shaped, the traditional die-cutting cannot meet the current composite material manufacturing industry. With the high utilization rate of materials, high cutting efficiency, and high material Undeformed needs, enterprises have to demand new solutions to solve these problems.

-

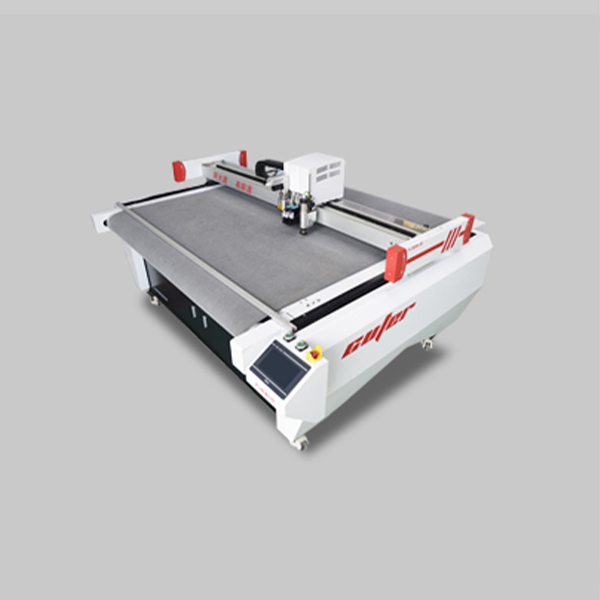

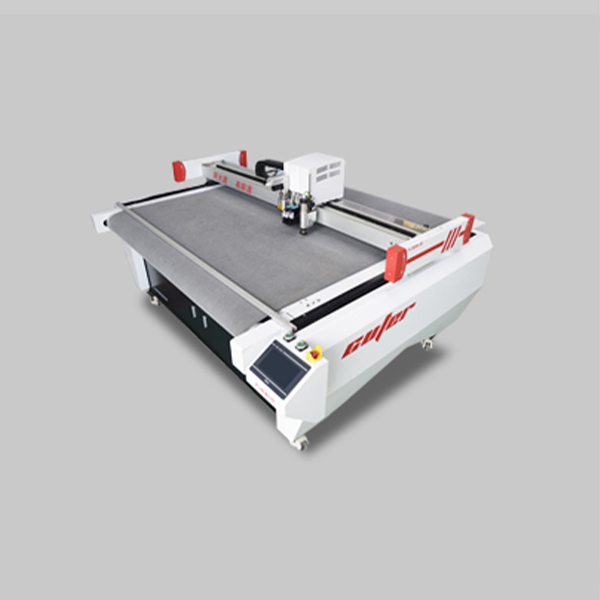

Manufacturing Companies for Zero Defect Automatic Digital Oscillating Knife Cutting Machine

Strengthening technological innovation by using intelligent clothing design and manufacturing equipment to achieve the purpose of “machine substitution” is an inevitable means of transformation and innovation. The CNC vibrating knife cutting machine will be your right-hand assistant.

-

Top Quality 3040b Mini Desktop CO2 Laser Engraving Machine Laser Cutting Machine CNC Laser Cutter Engraver for Acrylic Leather Wood Glass Crystal with 40W 50W 60W Optional

With the continuous development of the color box packaging industry, the industry materials are also diverse, such as corrugated hollow board, non-woven composite hollow board, sponge, PU foam, corrugated paper, cardboard, etc. These are typical soft materials. With the continuous increase of material types, the color box packaging industry has higher and higher requirements for material cutting. Traditional manual cutting or stamping can no longer meet the diversified cutting needs in this industry. The introduction of advanced equipment and the search for new solutions have become enterprise Imperative.

-

Factory Promotional High Speed CNC Gasket Cutting Machine Rubber Asbesots Cork PTFE Felt Material Handling Equipment Digital Gasket Making

The non-metallic material in the gasket material is a typical soft material, and its shape is circular primarily. It is difficult to cut manually, and the output is low. To improve the production quantity and quality, it is imperative to introduce automatic cutting equipment.

-

IOS Certificate Car Mat Floor PVC Loop Carpet Manufacturing Cushion Production Conveyor Table Cutting Machine

Strengthening technological innovation by using intelligent clothing design and manufacturing equipment to achieve the purpose of “machine substitution” is an inevitable means of transformation and innovation. The CNC vibrating knife cutting machine will be your right-hand assistant.

-

100% Original Factory Digital Oscillating Knife CNC Cutting Machine for Pet Sound-Absorbing Panels EVA EPE Foam

Due to the particularity and easy deformation of composite materials, the material cost is high. At the same time, considering that the data of the material pieces are mostly special-shaped, the traditional die-cutting cannot meet the current composite material manufacturing industry. With the high utilization rate of materials, high cutting efficiency, and high material Undeformed needs, enterprises have to demand new solutions to solve these problems.

-

Factory source CCD Camera and Bluetooth Connection, Cardboard, Foam Board, Polyvinyl Chloride Graphics Packaging Board Cut Digital Die Cutter

Due to the particularity and easy deformation of composite materials, the material cost is high. At the same time, considering that the data of the material pieces are mostly special-shaped, the traditional die-cutting cannot meet the current composite material manufacturing industry. With the high utilization rate of materials, high cutting efficiency, and high material Undeformed needs, enterprises have to demand new solutions to solve these problems.

-

OEM/ODM Factory Automated Flexo Printing Slotting Die Cutting Folding Gluing Corrugated Carton Box Making Machine

With the continuous development of the color box packaging industry, the industry materials are also diverse, such as corrugated hollow board, non-woven composite hollow board, sponge, PU foam, corrugated paper, cardboard, etc. These are typical soft materials. With the continuous increase of material types, the color box packaging industry has higher and higher requirements for material cutting. Traditional manual cutting or stamping can no longer meet the diversified cutting needs in this industry. The introduction of advanced equipment and the search for new solutions have become enterprise Imperative.

-

Supply ODM Computer Contral Digital Cutter CNC Oscillating Knife Genuine Leather Cutting Machine

With the continuous improvement of people’s living and consumption levels, all kinds of bags have become indispensable accessories for people. Leather goods are boxes, bags, gloves, ticket holders, belts, and other leather goods made of leather and non-leather materials. The leather goods industry includes luggage, handbags and small leather products made of natural leather materials and substitute materials.

-

Factory made hot-sale Sofa Cutting CNC Oscillating Knife Cutter Price

With the continuous improvement of people’s living and consumption levels, all kinds of bags have become indispensable accessories for people. Leather goods are boxes, bags, gloves, ticket holders, belts, and other leather goods made of leather and non-leather materials. The leather goods industry includes luggage, handbags and small leather products made of natural leather materials and substitute materials.

-

IOS Certificate Vibrating Knife Cutting Machine Oscillating Knife Cutter for Fiberglass Fabric, Garment, PVC

The non-metallic material in the gasket material is a typical soft material, and its shape is circular primarily. It is difficult to cut manually, and the output is low. To improve the production quantity and quality, it is imperative to introduce automatic cutting equipment.

-

Well-designed Gasket Digital Cutter Gasket Flatbed Cutter Gasket Digital Cutting

With the continuous development of the automobile industry and the maturity of the automobile market, the level of interior design, materials, and craftsmanship of automobiles has also been continuously enhanced. Consumers’ consumption concept has also been constantly changing and becoming more fashionable. Health and environmental protection, lightweight, high technology, and sustainability are the inevitable trends in developing automotive interior materials in the future.