We stay with our company spirit of “Quality, Performance, Innovation and Integrity”. We goal to create more value for our clients with our abundant resources, advanced machinery, experienced workers and superb solutions for Fast delivery WPC Foam Board Wooden Board Extrusion Machine with Printing and Cutting Machine, Our tenet is “Reasonable prices, efficient production time and best service” We hope to cooperate with more customers for mutual development and benefits.

We stay with our company spirit of “Quality, Performance, Innovation and Integrity”. We goal to create more value for our clients with our abundant resources, advanced machinery, experienced workers and superb solutions for China PVC Panel Making Machine and PVC Ceiling Production Line, In order to meet more market demands and long-term development, a 150, 000-square-meter new factory is under construction, which will be put into use in 2014. Then, we shall own a large capacity of producing. Of course, we will continue improving the service system to meet the requirements of customers, bringing health, happiness and beauty to everyone.

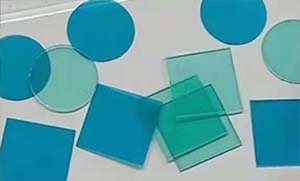

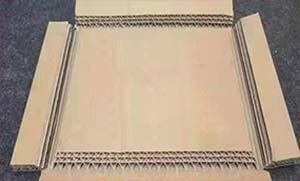

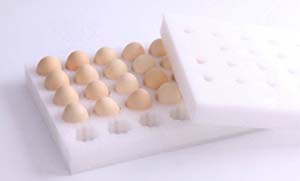

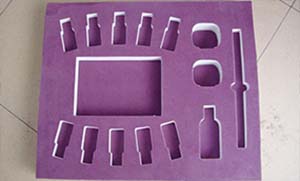

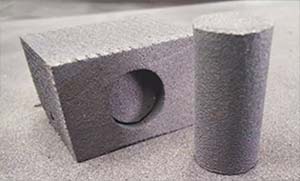

Advertising products include plastic light boxes, inkjet materials, reflective materials, engraving materials, display equipment, self-adhesive stickers, photo consumables, advertising boards, advertising accessories, optoelectronic equipment, etc. With the continuous development of the advertising industry, the industry materials are also various, such as PVC foam board, photo-adhesive KT board, Chevron board, cardboard, inkjet cloth, acrylic, aluminum-plastic panel, etc. These are typical soft materials. With the continuous increase in material types, the advertising industry has higher and higher requirements for material cutting. Traditional manual cutting or stamping can no longer meet the diversified cutting needs in this industry. Enterprises must introduce advanced equipment and find new solutions—a must-do.

Among various forms of paper packaging, color box packaging has developed the most rapidly. It is widely used in tobacco, food, medicine, daily chemicals, and other fields related to people’s lives, and the demand is still expanding.

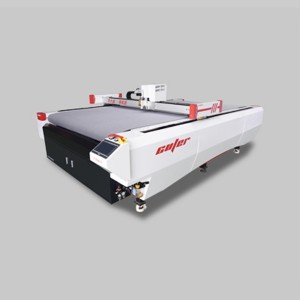

For the advertising and packaging industry, the vibrating knife cutting machine can quickly locate and identify, automatically find the edge and cut, which greatly reduces the workload of the operator. It is suitable for cutting and production of KT board, Chevron board, self-adhesive, corrugated honeycomb board and other materials.

|

Equipment Model |

DT-2516A /DT1328F |

|

Scope Of Work |

2500x1600mm/1300x2800mm |

|

Drive System |

Imported Mitsubishi Servo Motor Drive |

|

Transmission System |

Pmi Linear Guide Rail, Precision Rack Drive |

|

Maximum Cutting Speed |

1800mm/s |

|

Cutting Material |

Pvc Foam Board, Photo-Adhesive Kt Board,Cardboard, Inkjet Cloth, Acrylic,Corrugated Paper Etc. |

|

Cutting Tools |

Vibrating Kinfe, Round-Kinfe, v-Cut Knife, Milling Knife, Kiss-Cut Knife Etc. |

|

Cutting Thickness |

0.1-30mm (Subject To Specific Materials) |

|

Cutting Accuracy |

±0.01mm |

|

Repetition Accuracy |

±0.03mm |

|

Feeding Method |

Automatic Feeding(DT-2516A)/ Manual Feeding(DT-1328F) |

|

Fixing Method |

All Aluminum Table Vacuum Adsorption |

|

Transmission Interface |

Usb/u Disk/Network |

|

Power Supply And Power Of Cutting Equipment |

220v/50hz 2.5kw |

|

Power Supply And Power Of Vacuum Pump |

380v 7.5kw/9kw (Optional) |

|

Positioning Method |

Infrared Laser, Ccd Camera (Optional) |

|

Safety Device |

Infrared Laser Induction, Safe And Stable |

|

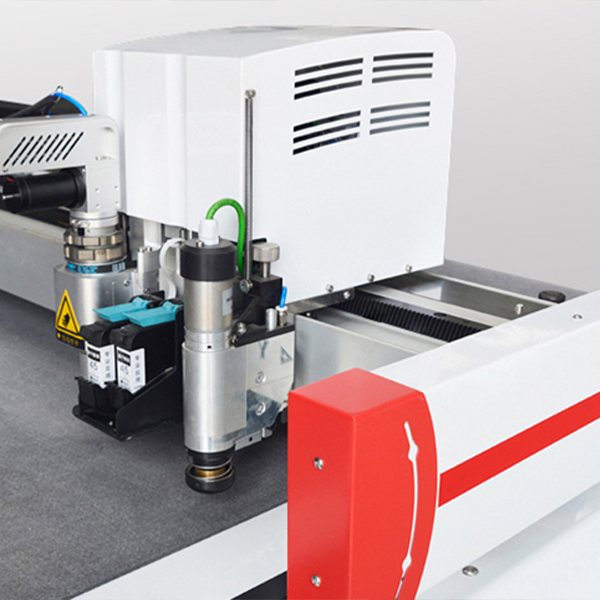

Pneumatic Fittings |

Festo, Germany/Yadek, Taiwan |

|

Electrical Fittings |

Chint/Delixi |

Datu Vibration Knife cutting machine has very rich experience and complete solutions in the advertising and packaging industry. It’s capable of PVC foam board, photo-adhesive KT board, Chevron board, cardboard, inkjet cloth, acrylic, aluminum-plastic board, self-adhesive, and other materials that are often used in plastic light boxes, spray painting, carving, display equipment, self-adhesive stickers, photo, advertising board, optoelectronic equipment, etc. We have extensive experience and relevant solutions for this. Replacing the indentation knife can make a packaging box without making a die. Replacing the milling cutter module can realize the function of the engraving machine. Replacing the kiss-cut knife module can realize the cutting of self-adhesive characters. It can quickly complete various processes such as full cutting, half cutting, routing, drilling, creasing, marking, etc. All functions can be completed on one machine. It can help users to process advertising products more quickly and accurately within a limited time and space, thereby more effectively improving the industrial competitiveness of advertising production users.

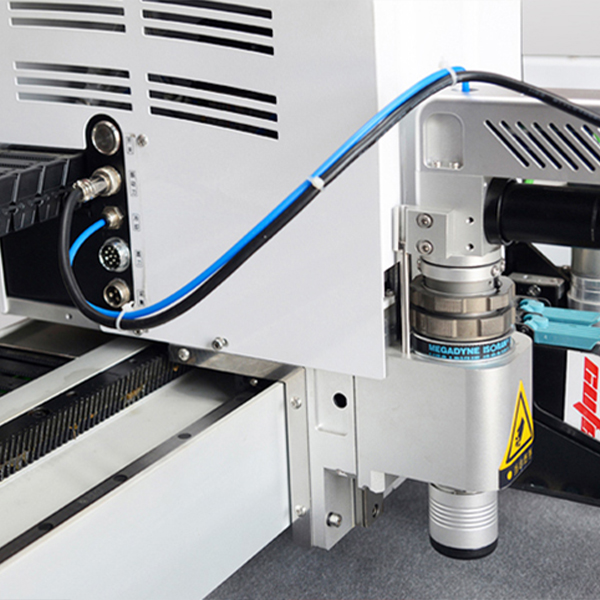

1. Round cutters, vibrating cutters, pneumatic cutters, kiss-cut cutters, V-cutters, milling cutters, and more cutting configurations.

2.1800MM/S high speed, 0.01MM repeat positioning accuracy.

3. Mitsubishi servo motors, Taiwan Hindwin guide rails and other brand electrical components, double rack machines are more durable

4. Equipped with a large visual intelligent edge inspection system, cutting and proofing are faster.

5. Data import and direct cutting, no paper version is required. save time

6. Support for multiple file formats (AI, PLT, DXF, CDR, etc.), making it more convenient to use and interact with.

Applicable tools: vibrating kinfe, round-kinfe, V-cut knife, milling knife, kiss-cut knife

Applicable models: DT-2516A DT-1328F

(1) One-year warranty policy.

(2) 7*24-hour online service.

(3) Provide lifetime free technology upgrade service.

(4) Free training in our factory, if time is not convenient, we can also provide complete training video.

(5) On-site technical support can be provided by negotiation.

We stay with our company spirit of “Quality, Performance, Innovation and Integrity”. We goal to create more value for our clients with our abundant resources, advanced machinery, experienced workers and superb solutions for Fast delivery WPC Foam Board Wooden Board Extrusion Machine with Printing and Cutting Machine, Our tenet is “Reasonable prices, efficient production time and best service” We hope to cooperate with more customers for mutual development and benefits.

We stay with our company spirit of “Quality, Performance, Innovation and Integrity”. We goal to create more value for our clients with our abundant resources, advanced machinery, experienced workers and superb solutions for Fast delivery WPC Foam Board Wooden Board Extrusion Machine with Printing and Cutting Machine, Our tenet is “Reasonable prices, efficient production time and best service” We hope to cooperate with more customers for mutual development and benefits.

Fast delivery China PVC Panel Making Machine and PVC Ceiling Production Line, In order to meet more market demands and long-term development, a 150, 000-square-meter new factory is under construction, which will be put into use in 2014. Then, we shall own a large capacity of producing. Of course, we will continue improving the service system to meet the requirements of customers, bringing health, happiness and beauty to everyone.

-

8 Years Exporter China Plastic Crusher Price Au...

-

China Wholesale Glass Fiber Mesh Fabric, Textil...

-

Factory Cheap Hot 1325 CNC Printing Marking Mac...

-

Hot Selling for Manufacture CNC Vibration Knife...

-

Factory source 2022 New Corrugated Board Cardbo...

-

Best-Selling Car Seat Cover and Car Mat Auto Fe...