Factory Supply Cutter Fabric - Digital Cutting System Module – Datu Detail:

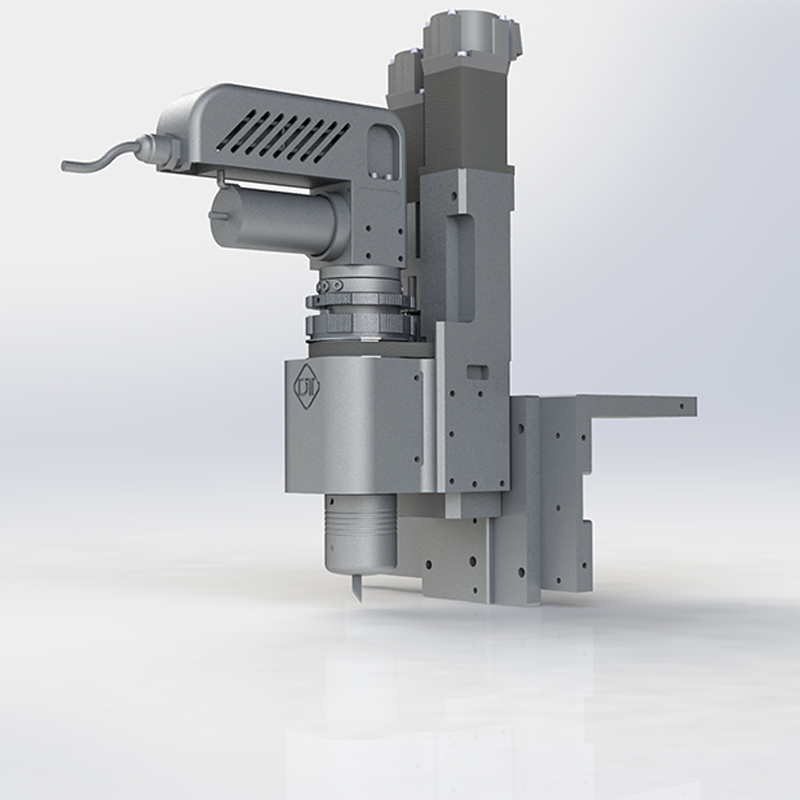

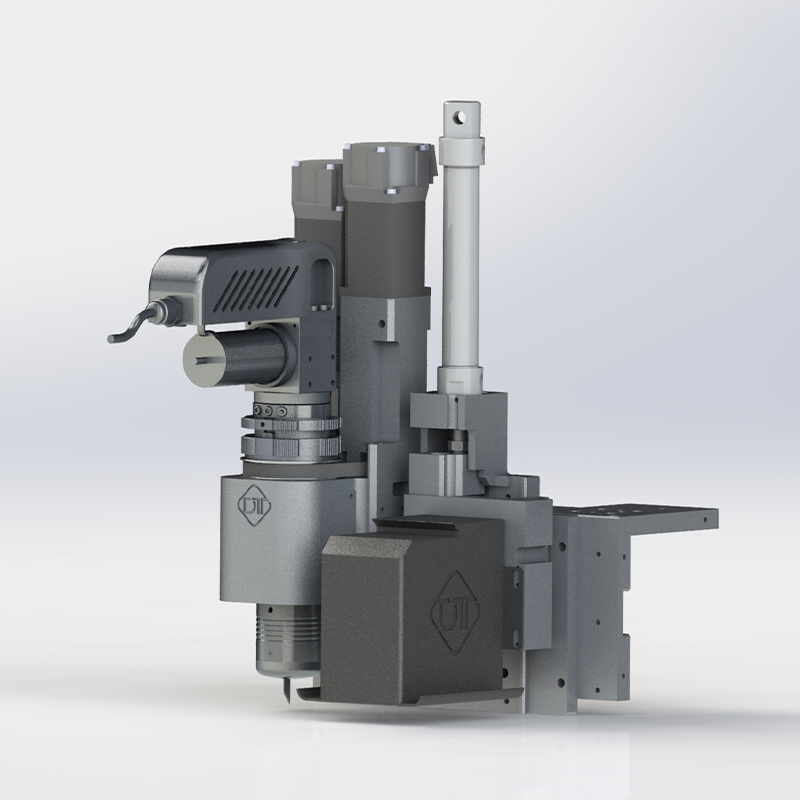

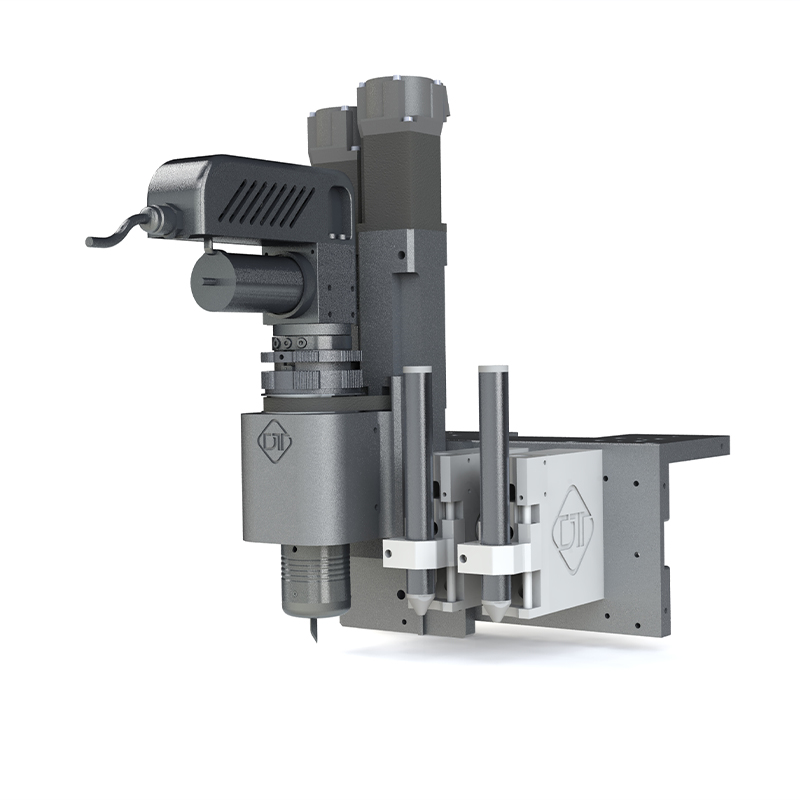

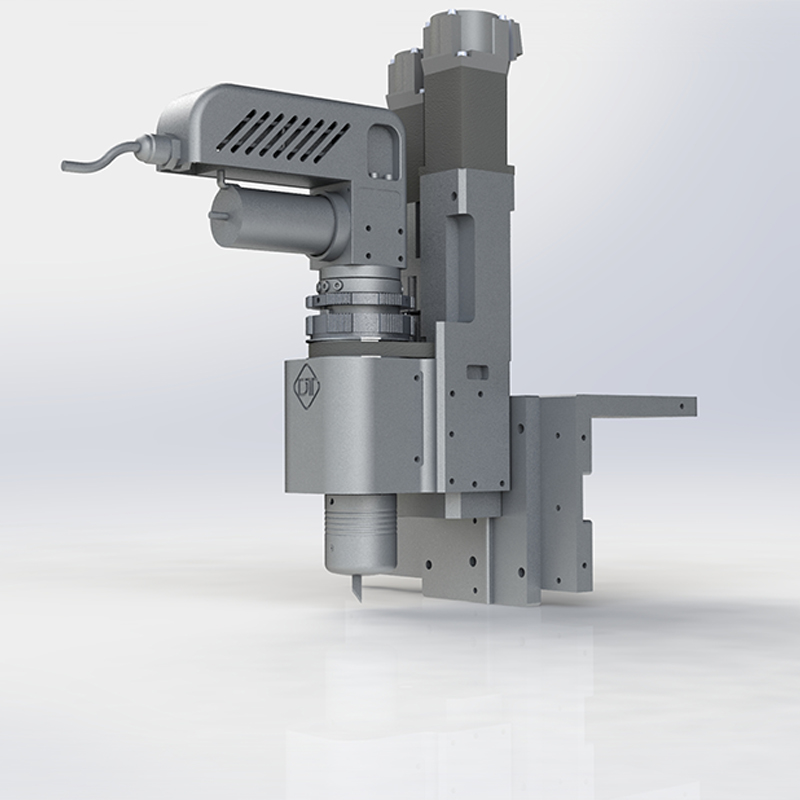

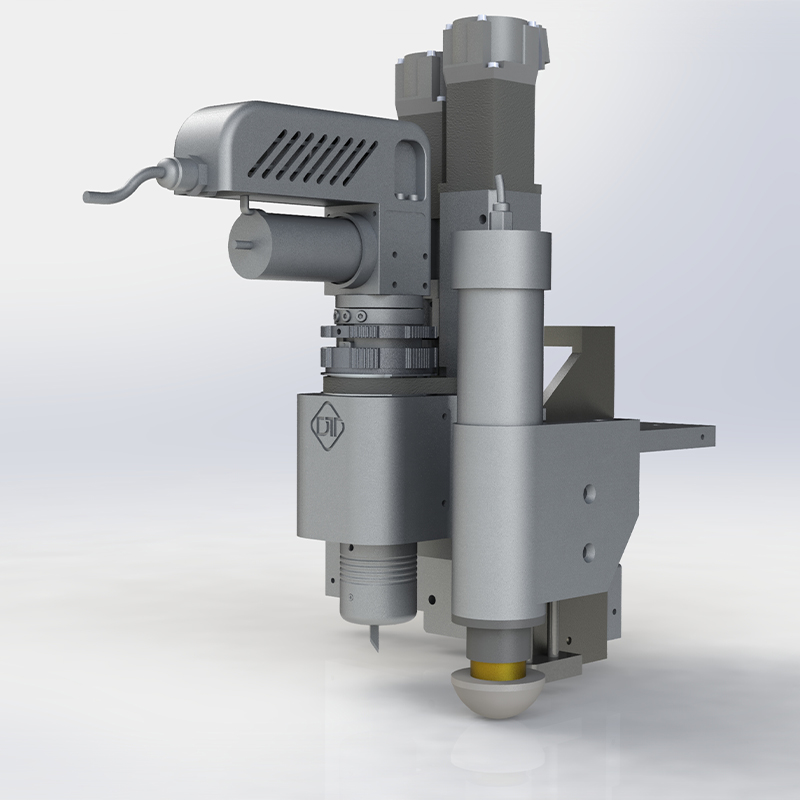

Single Oscillating Knife Tool

Details:

·Servo motor drive

·Tool mounting diameter 40mm

·PMI guide rail & slider

·Screw pitch 0.2mm

·Stroke 80mm

·Red light indicator (5V/24V optional)

·24V limit switch (NPN/PNP)

Applicable Tools:

electric vibrating knife, pneumatic knife, V-cut knife, round knife, kiss cut knife, drag knife, creasing knife.

Application Scenario:

Cutting various flexible materials with different knives, replace the blades according to the materials.

Application Industry:

Advertising KT board, foam board, corrugated paper, cardboard, silk ring foot pad, leather, carpet, gasket, carbon fiber and other flexible materials cutting industries.

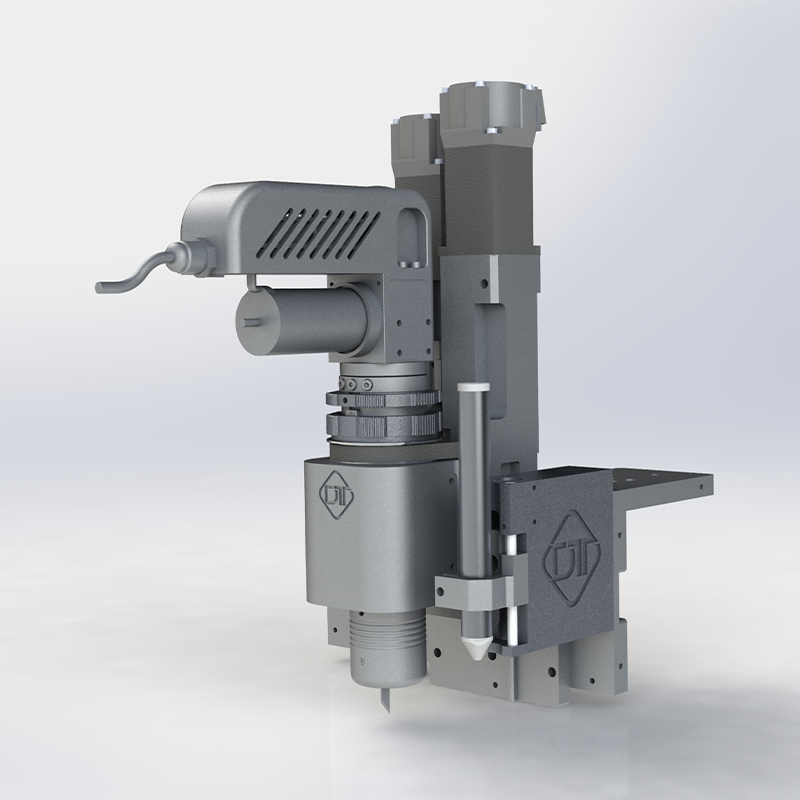

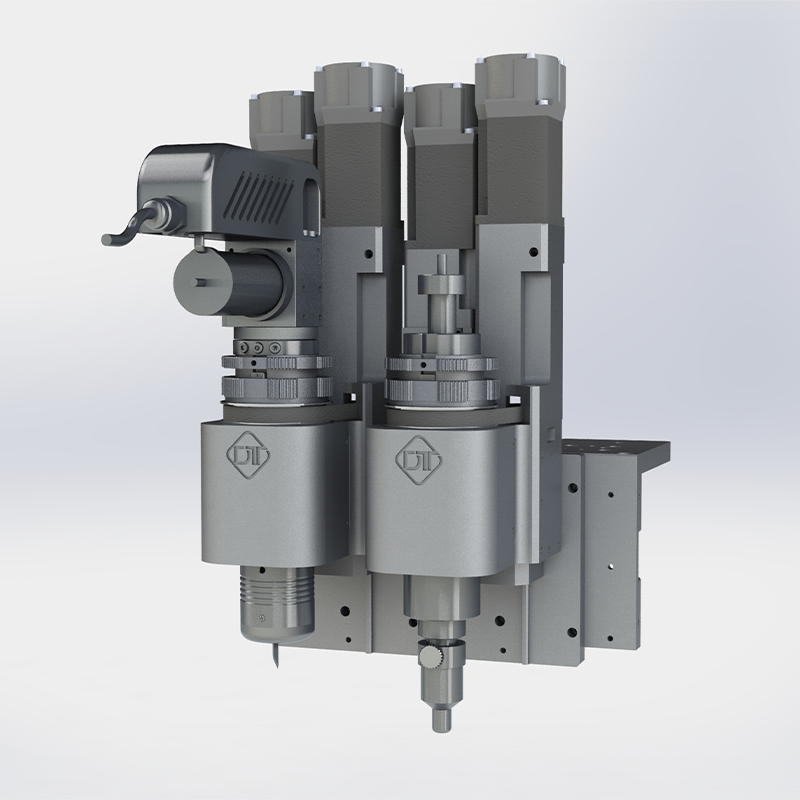

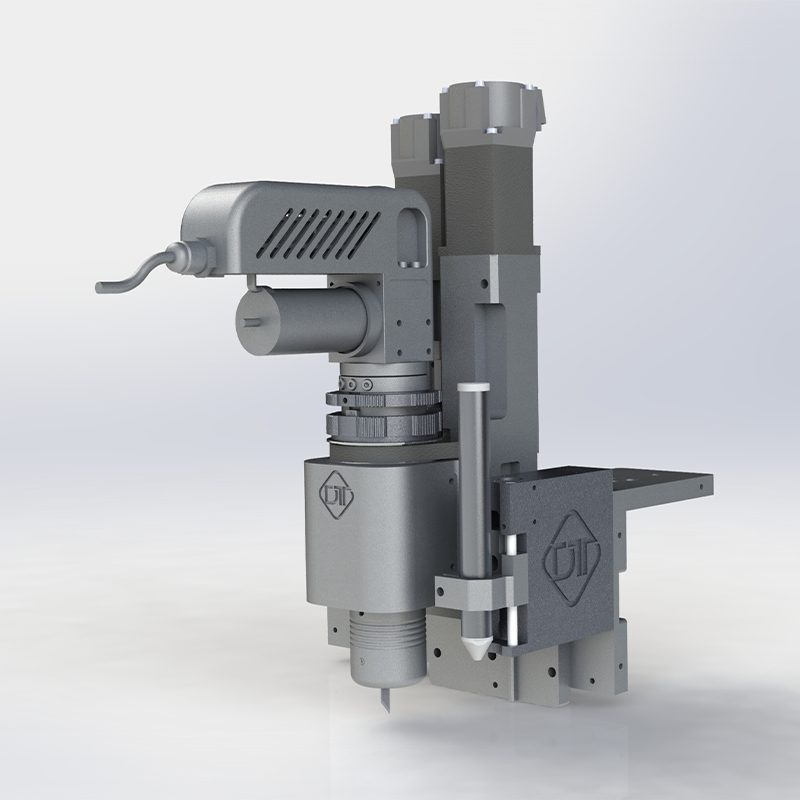

Single Oscillating Knife Tool + Drawing Tool

Details:

·Adopt high strength spring

·Speed adjustable

·Compatible with a variety of pens

·Pneumatic drive

·Drawing holder adjustable height 0-60mm

·Drawing stroke 20mm

·Markable on most colorable materials

Drawing Function:

Writing text, making marks, drawing graphics.

Application Scenario:

It can be equipped with different pens to mark various materials before cutting.

Cutting Materials:

Leather, cloth, cardboard, carpet, advertising KT board, corrugated paper, etc.

Applicable Industries:

Industries that need to be marked/plotted before cutting, such as the sofa industry, clothing industry, shoemaking industry, automotive interior industry, luggage industry, etc.

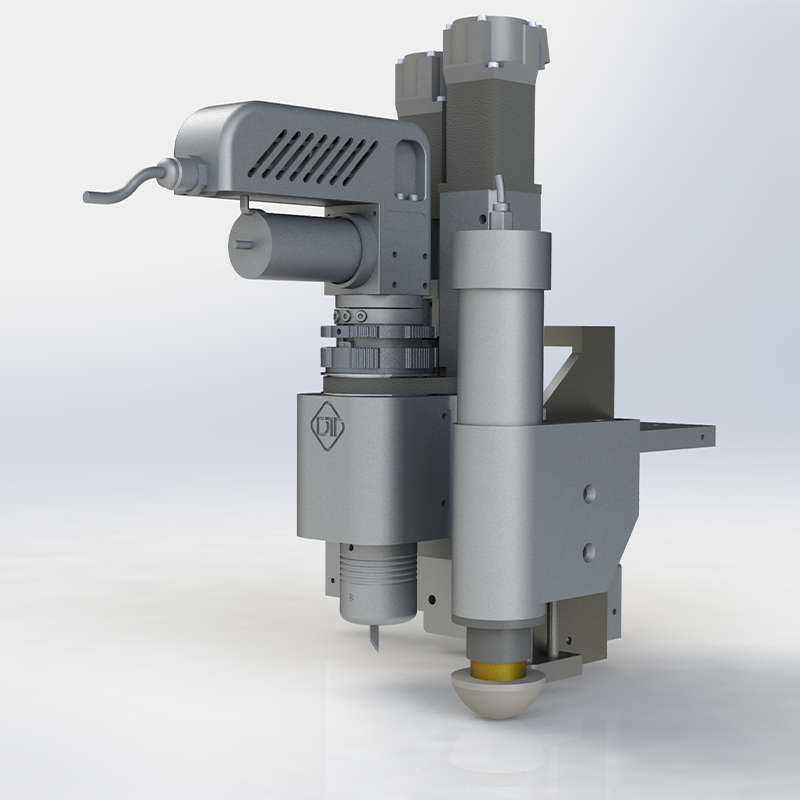

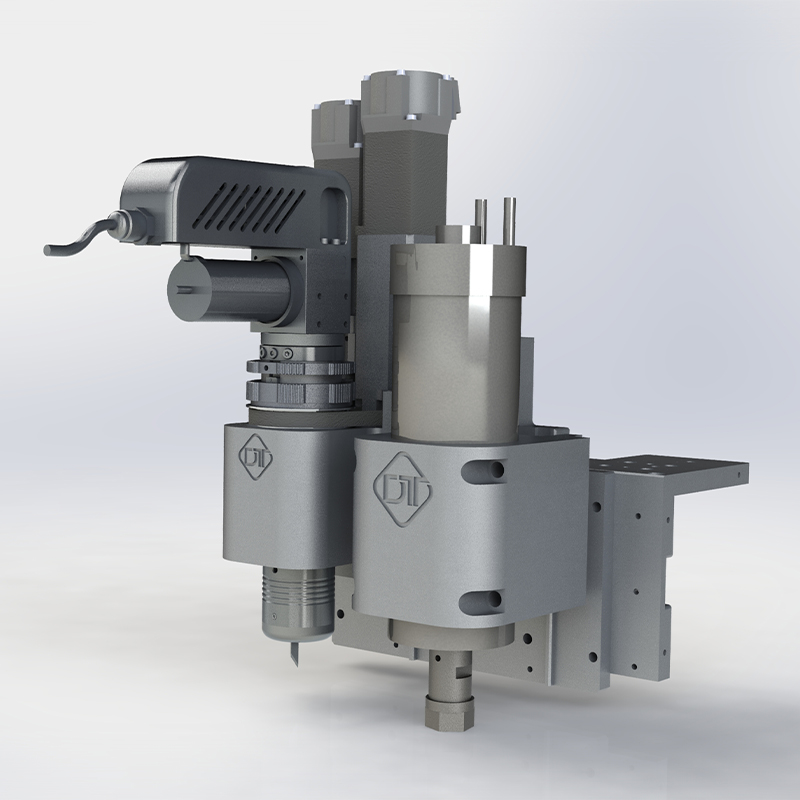

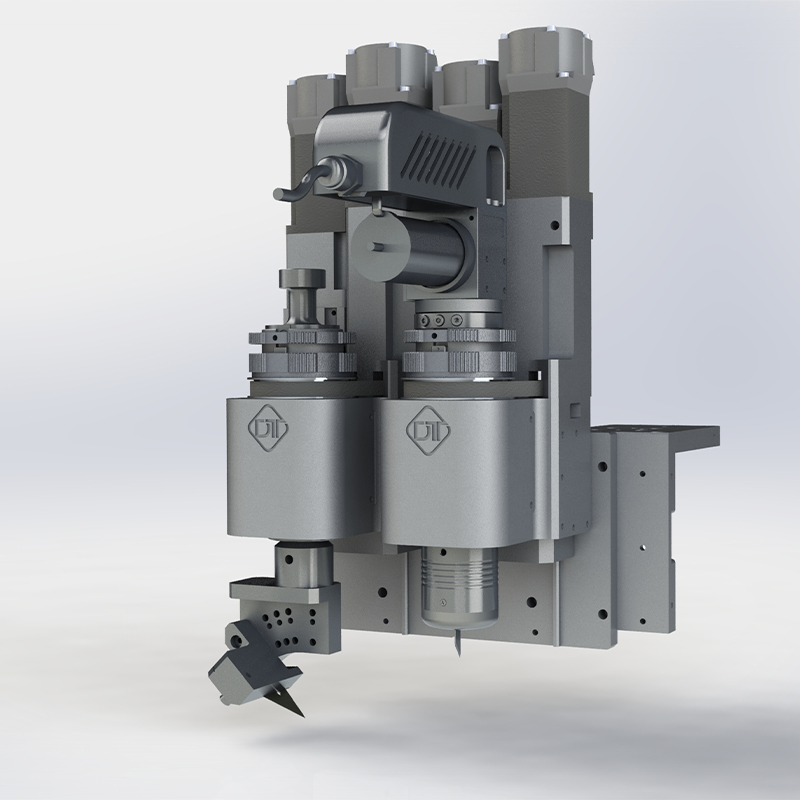

Single Oscillating Knife Tool + Punching Tool

Details:

·High efficiency

·Low noise

·With blowing function

·Punching frequency is adjustable

·Pneumatic drive

·Cylinder stroke 20mm

·Rotating Speed:5000r/min

·Punching diameter 1-6mm

Punching Knife Function:

The cylinder drives the high-speed rotating punch up and down to punch holes in the material.

Cutting Materials:

Cloth, leather, honeycomb board, KT board, cardboard, etc.

Applicable Industries:

Automotive interior industry, clothing industry, sofa industry, luggage industry, shoemaking industry, etc.

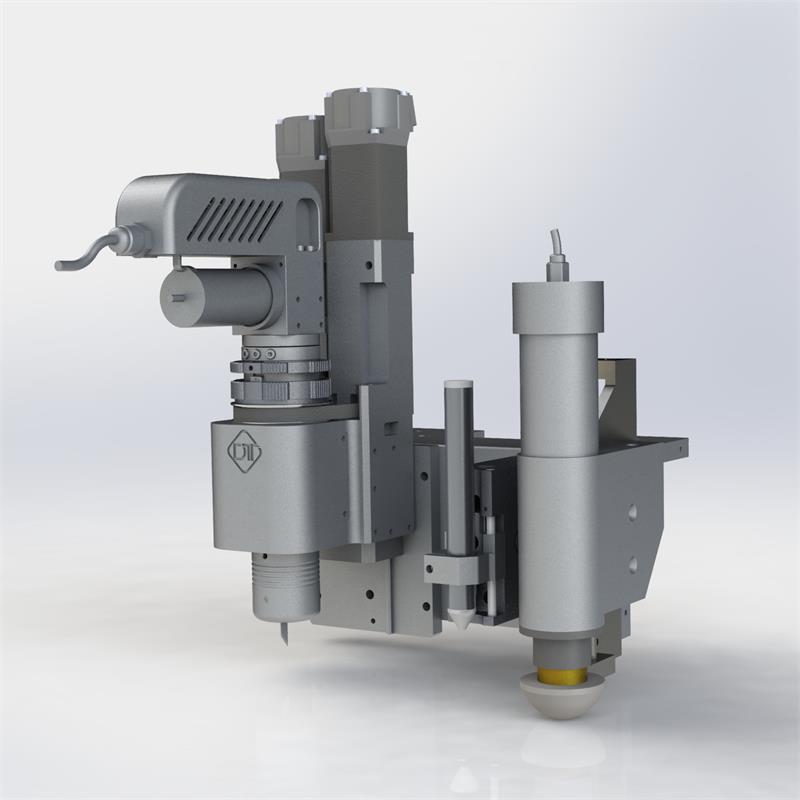

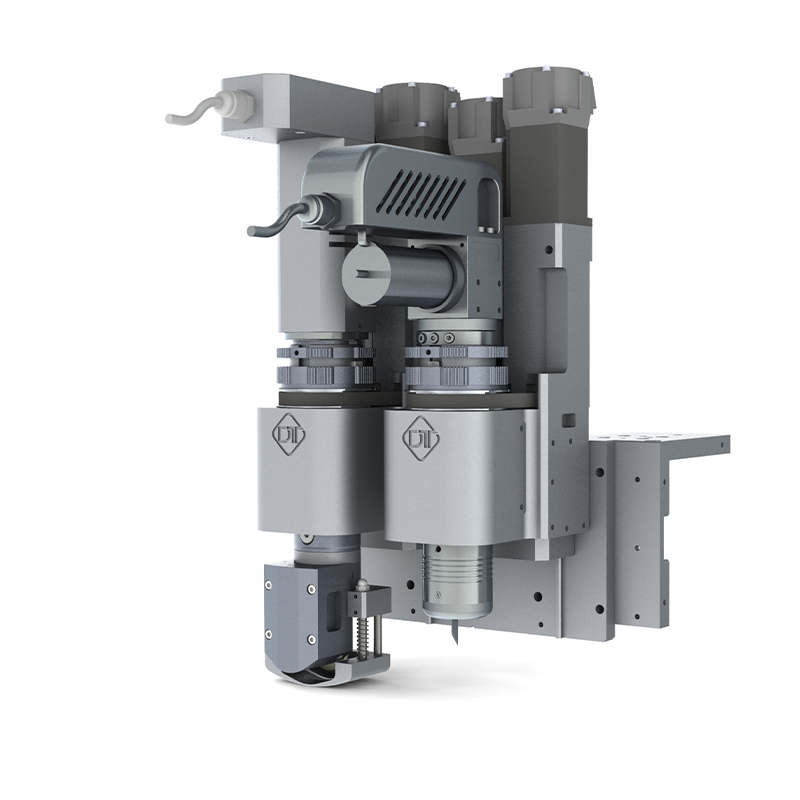

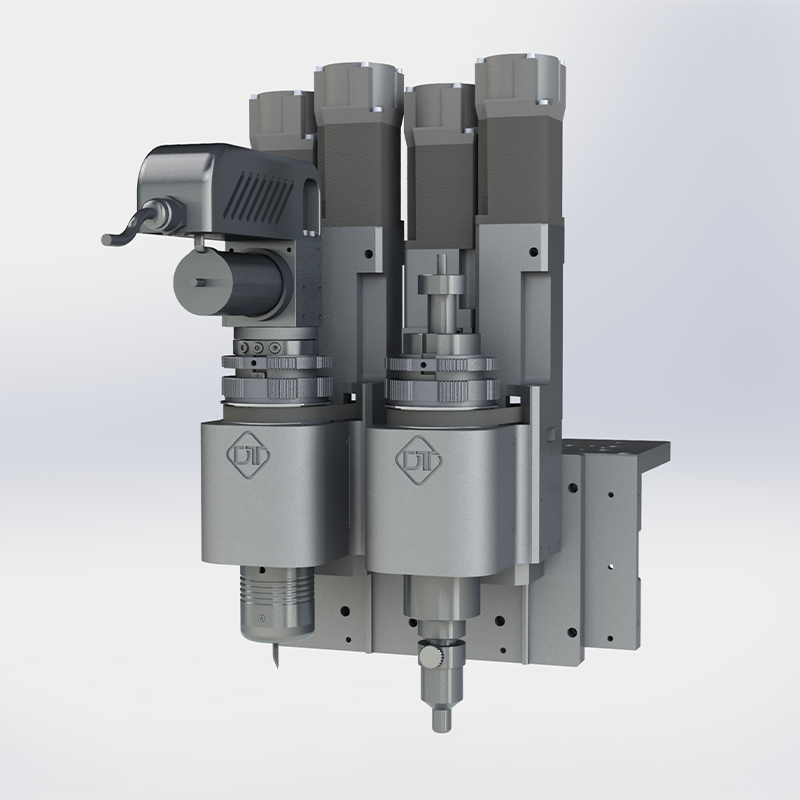

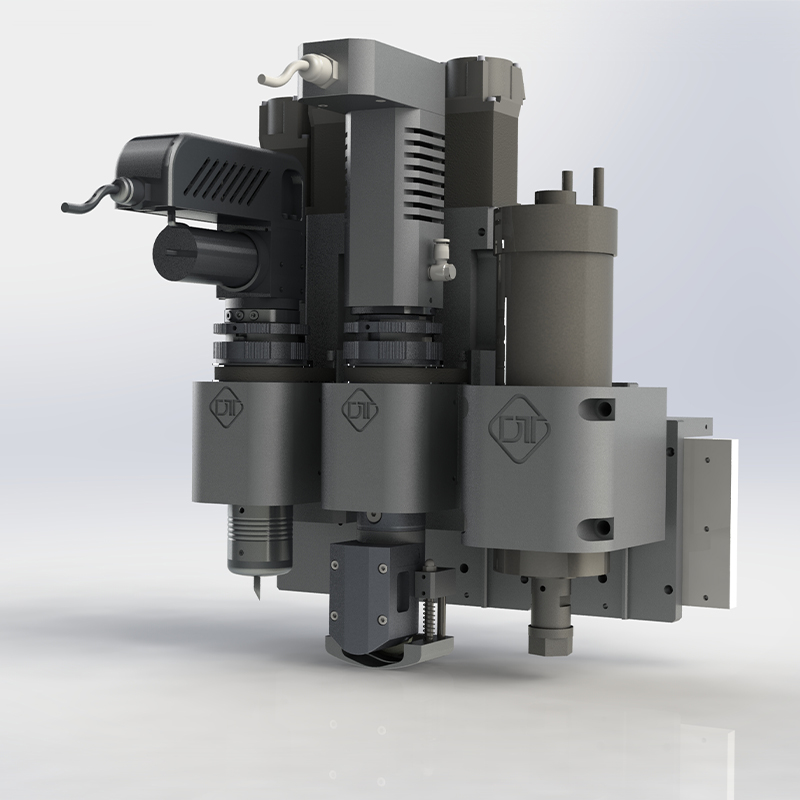

Single Oscillating Knife Tool + Drawing Tool + Punching Tool

Function:

A single knife holder with a punching tool and drawing tool can complete marking, punching and cutting work.

Cutting Materials:

Cloth, leather, honeycomb board, KT board, cardboard, etc.

Applicable Industries:

Automotive interior industry, clothing industry, sofa industry, luggage industry, shoemaking industry, etc.

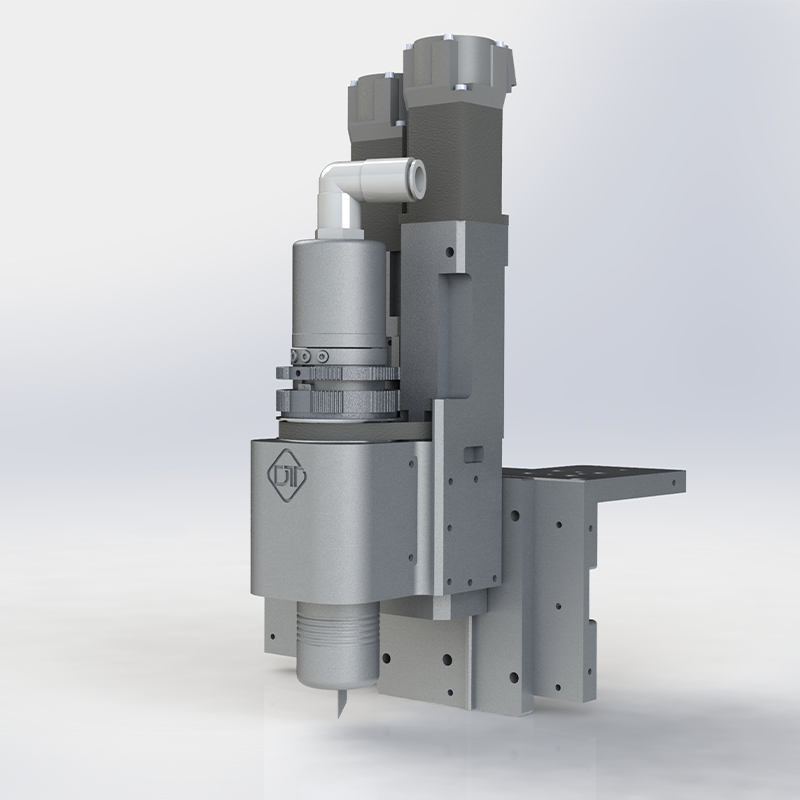

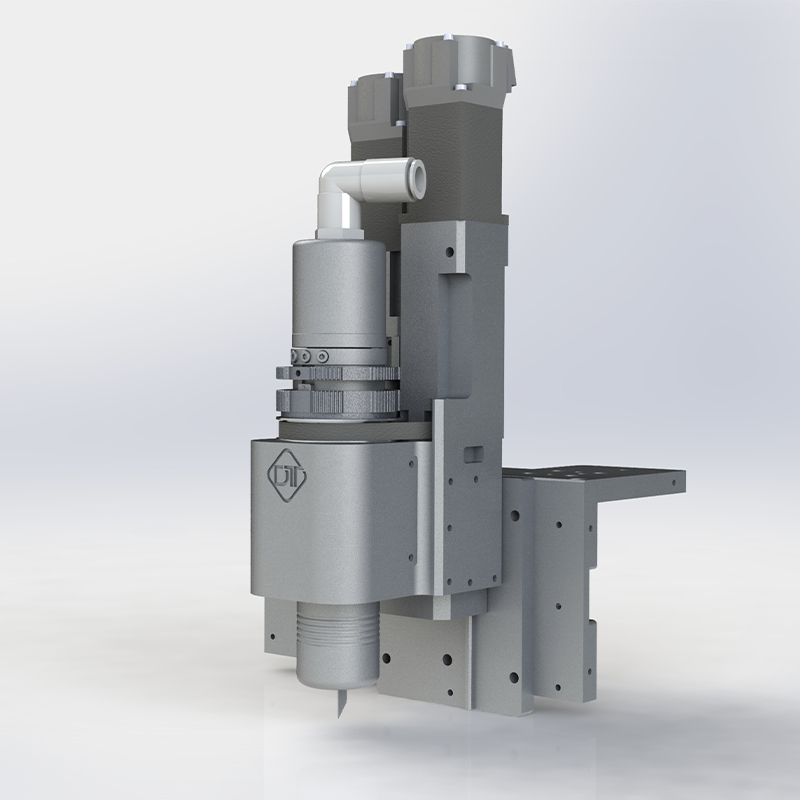

Single Oscillating Knife Tool + Inkjet Tool

Working Principle:

Before cutting, quickly spray patterns, text, etc., on the material for marking.

Advantages:

faster and more efficient than brush marking, suitable for large processing areas with many markings.

Sprayable Materials:

All colorable materials.

Cutting materials:

Cloth, leather, honeycomb board, KT board, cardboard, etc.

Applicable Industries:

Automotive interior industry, clothing industry, sofa industry, luggage industry, shoemaking industry, etc.

Single Oscillating Knife Tool + Spindle

Datails:

·Spindle Voltage: 220V

·Spindle Diameter: 65mm

·Drive Mode: Inverter drive

·Rotating Speed:0—40000r/min

·Lifting Drive Mode:servo motor

The spindle motor with a milling knife is a high-power and high-speed motor driven by a frequency converter, with adjustable speed and high load advantages. It can realize the cutting of various materials through different speed choices and cutter heads. It can be equipped with air-cooled or water-cooled cooling functions. Work with the single oscillating tool or other tools to realize multiple cutting purposes.

Machinable materials:

Acrylic board, MDF, aluminum-plastic board, Chevron board, PE board, wood, hard plastic and other high-density hard materials.

Applicable industries:

Advertising industry, home improvement industry, plastic processing industry.

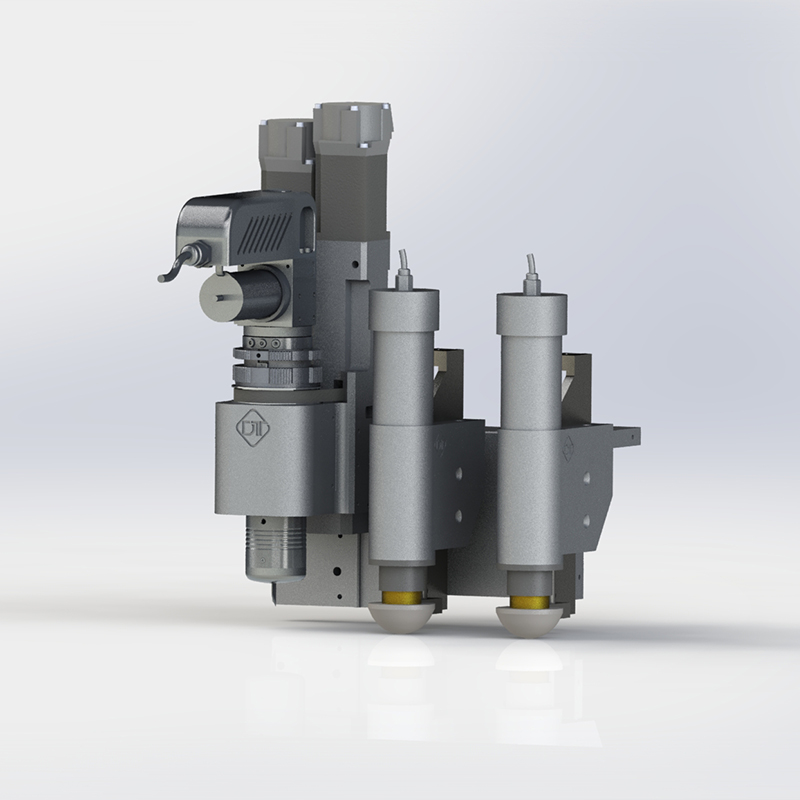

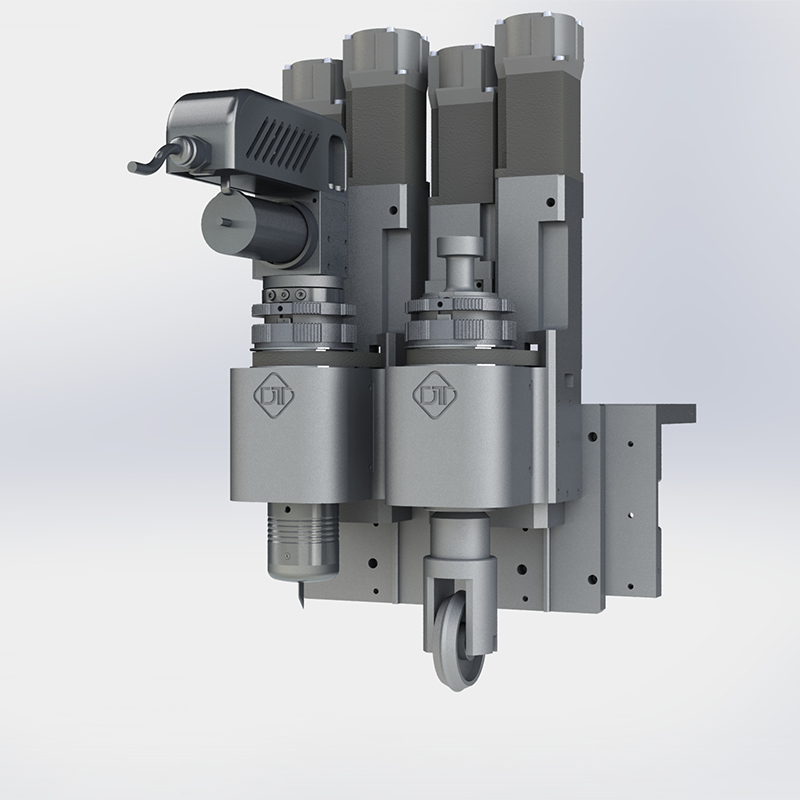

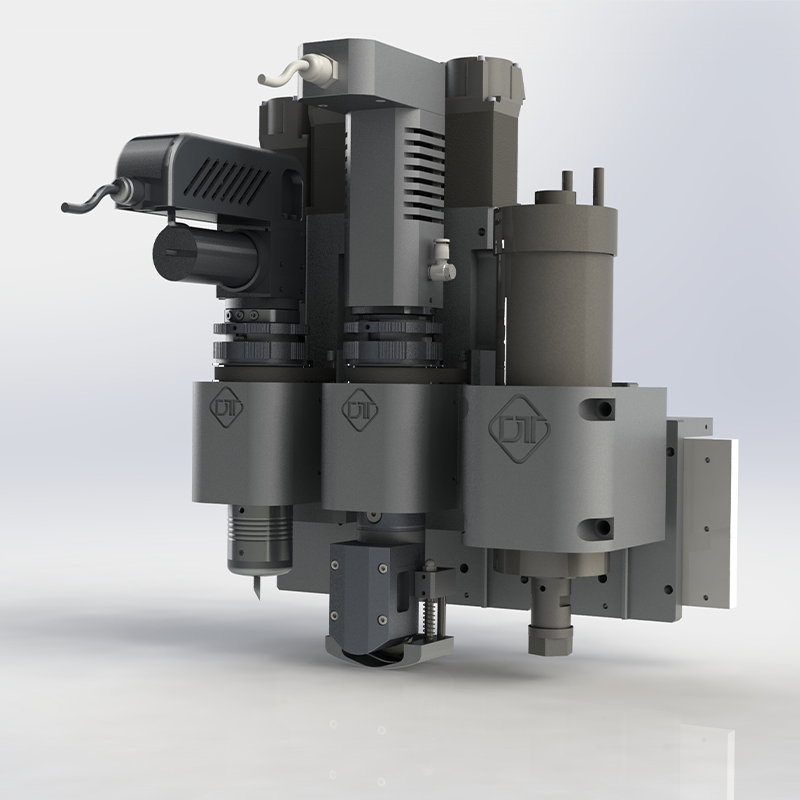

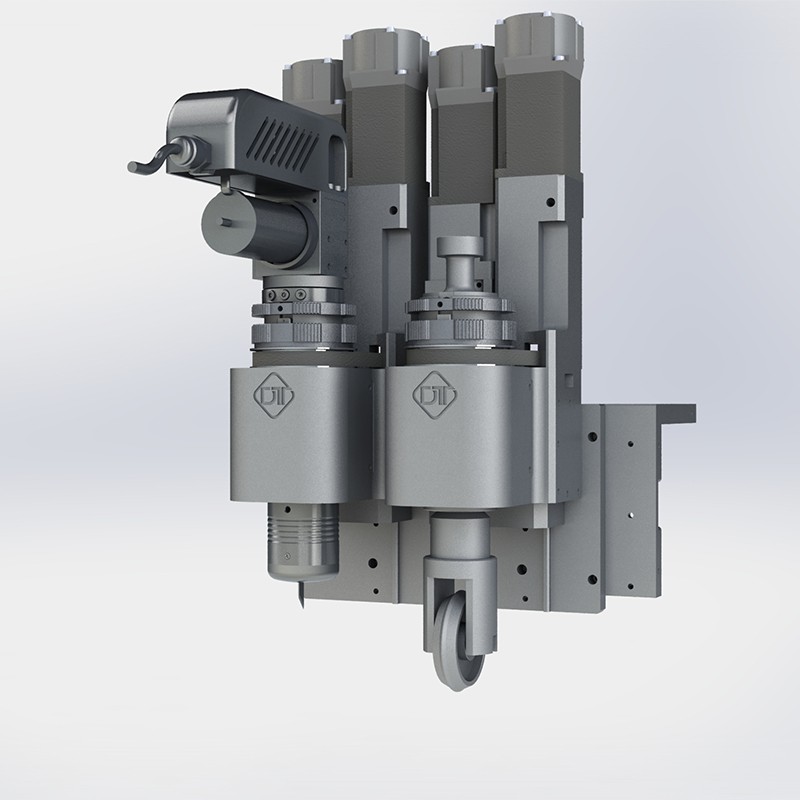

Single Oscillating Knife Tool + Double Punching Tools

Under the system’s control, by using different punching knives, two kinds of holes can be processed in one work, and the processing of different patterns or spots with different diameters can be completed. Working with an oscillating knife can realize the punching and cutting functions of the material.

Processing Materials:

Cloth, leather, etc.

Applicable Industries:

Automotive interior industry, leather goods industry, luggage and clothing industry, furniture industry, etc.

Single Pneumatic Oscillating Knife Tool

Details:

·Drive Mode:pneumatic

·Amplitude:8-15mm

·Working Air Pressure:0.8Mpa

·Blade Thickness:0.63 / 1 / 1.2mm

The blade driven by the compressed air reciprocates at high speed to cut the material. It is suitable for soft and thick fabrics with medium and low density or thin materials with high density and rigid material. It can be matched with different blades to realize the processing of different materials.

Processable Materials:

Ceramic fiber, thermal insulation cotton, pearl cotton, sponge, EVA and other foam materials.

Applicable Industries:

Building materials industry, packaging industry, etc.

Single Oscillating Knife Tool + Double Drawing Tools

Double drawing tools can hold two different refills at the same time. Under the system’s control, patterns can be drawn with different pens in one process. Working with an oscillating knife tool, it can realize the function of drawing patterns and cutting.

Drawing Function:

Write text, make marks, draw graphics.

Application Scenarios:

Different refills can be added to the drawing tools to make marks or draw patterns before cutting.

Cutting Materials:

Leather, cloth, cardboard, carpet, advertising KT board, corrugated paper, etc.

Applicable Industries:

Industries that need to be marked before cutting, such as the sofa industry, clothing industry, shoemaking industry, automotive interior industry, luggage industry, etc.

The double tool holder can install two kinds of tools simultaneously, which can be alternately cut to meet different processing methods.

Application Scenarios:

1. Creasing Tool + Oscillating Knife Tool:

Use the creasing tool to crease the material first, and then use the oscillating tool to cut it. It can be used to process corrugated paper, cardboard, corrugated plastic board, and other materials and is suitable for the carton printing industry.

2. V-CUT Knife Tool + Oscillating Knife Tool:

Use the V-CUT tool to process V-shaped grooves and inclined surfaces of different specifications by changing the installation angle of the blade first, and then use a vibrating knife to cut the desired shape.

3. Kiss Cut Tool + Oscillating Knife Tool:

It’s suitable for cutting stickers and self-adhesive paper.

4. Round Knife Tool + Oscillating Knife Tool:

The vibrating knife is suitable for cutting materials with poor air permeability but good adsorption. The round cutter is usually used to cut materials with good air permeability but poor adsorption. This module can meet the cutting of the most flexible fabrics.

Processing Materials: Cloth, leather, PE, PP film, etc.

Applicable Industries: Automotive interior industry, leather goods industry, luggage and clothing industry, furniture industry, etc.

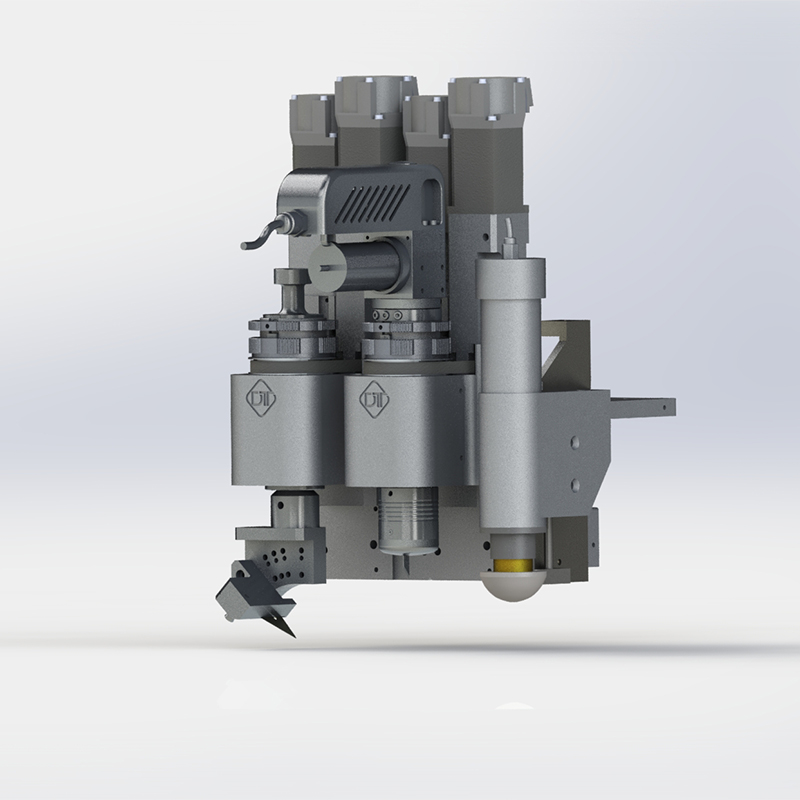

5. Oscillating Knife Tool + Round Knife Tool + Spindle:

Using the V-CUT knife to process V-shaped grooves and inclined surfaces of different specifications by changing the installation angle of the blade at first, then punching out the required holes with a high-speed punching tool, and finally cutting the needed shape with the vibrating knife.

Application industry: Advertising packaging industry, carton proofing industry, interior decoration industry, handicraft studio.

6. Oscillating Knife Tool + V-CUT Knife Tool + Punching Tool:

The spindle motor with a milling knife is a high-power and high-speed motor driven by a frequency converter, with adjustable speed and high load advantages. It can realize the cutting of various materials through different speed choices and cutter heads. It can be equipped with air-cooled or water-cooled cooling functions. Work with the single oscillating tool or other tools to realize multiple cutting purposes.

Details:

·Spindle Voltage: 220V

·Spindle Diameter: 65mm

·Drive Mode: Inverter drive

·Rotating Speed: 0—40000r/min

·Lifting Drive Mode: servo motor

Advantages:

The combination of various cutter heads can expand the coverage of processed products and meet more application scenarios.

Machinable materials:

acrylic board, MDF, aluminum-plastic board, Chevron board, PE board, wood, hard plastic and other high-density hard materials.

Applicable industries:

advertising industry, home improvement industry, plastic processing industry, handicraft studio.

Product detail pictures:

Related Product Guide:

We've got quite possibly the most state-of-the-art production gear, experienced and qualified engineers and workers, acknowledged top quality handle systems along with a friendly expert gross sales group pre/after-sales support for Factory Supply Cutter Fabric - Digital Cutting System Module – Datu, The product will supply to all over the world, such as: belarus, Guyana, Austria, With a team of experienced and knowledgeable personnel, our market covers South America, the USA, the Mid East, and North Africa. Many customers have become our friends after good cooperation with us. If you have the requirement for any of our products, please contact us now. We are looking forward to hearing from you soon.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.

-

Professional Factory For Heat Insulation Cuttin...

-

New Arrival China Knife Cutting Machine - Digi...

-

Top Quality Flexo Flatbed Plotter Cutter - Dig...

-

Europe Style For Pattern Cutting Plotter - Gas...

-

Top Quality Gasket Flatbed Cutter - Digital Cu...

-

Renewable Design For Cutter Machine - Digital ...