Factory Promotional Vibration Cutting Machine For Packaging - Gasket Digital Cutter – Datu Detail:

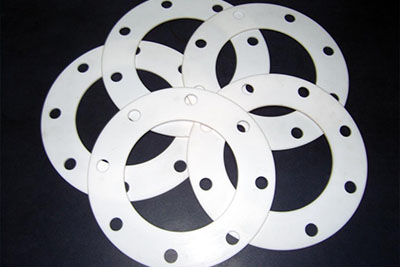

Gasket products include spacers and gaskets.

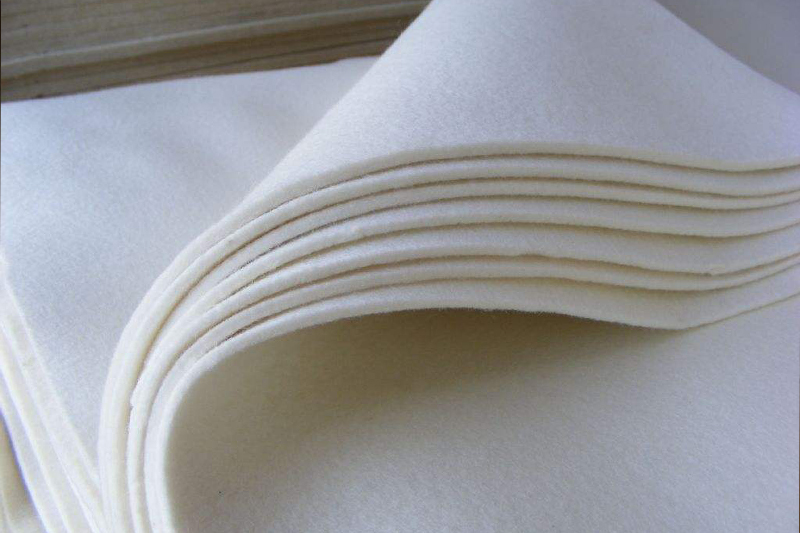

Gasket materials are typically sheet materials such as backing paper, rubber, silicone rubber, metal, cork, felt, neoprene, nitrile rubber, fiberglass, or plastic polymers such as Teflon. Gaskets for specific applications may contain asbestos. Non-metallic gaskets are non-metallic gaskets such as asbestos, rubber, synthetic resin, PTFE, etc.

Does anyone know what a gasket is? Gaskets seem to be uncommon in people’s daily production and life, but in fact it is not the case. Gaskets are widely used in various daily products, such as cylinder gaskets, rubber gaskets, etc. The material of the gasket is very rich and varied from simple paper to metal or silicone, so this requires the gasket cutting machine to provide the cutting function for a variety of materials.

The shape of the gasket in actual use is different, so the specific cutting and cutting difficulty and complexity are also very different. The gasket cutting machine solves the problem to the greatest extent according to the location of the problem. Generally speaking, the gasket cutting machine on the market is equipped with an intelligent cutting head, which can be adjusted and adjusted freely and flexibly. Practicality has been greatly improved.

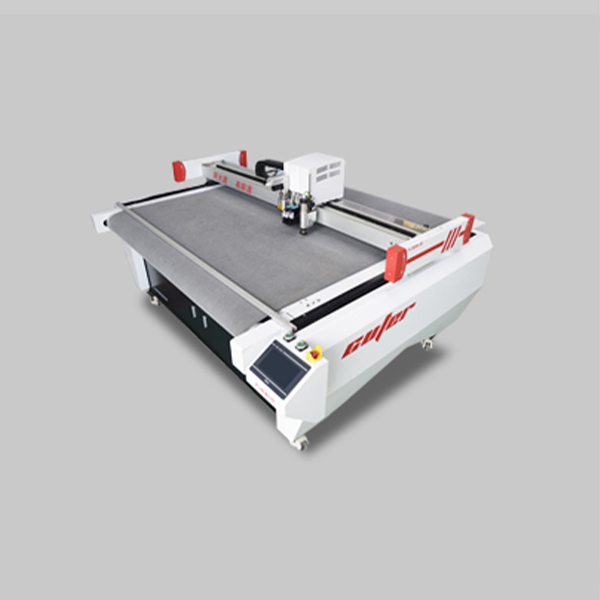

Our cutting machine for gasket is more suitable for small and medium batch sample cutting production.

|

Equipment Model |

DT-2516A /DT1328F |

|

Scope Of Work |

2500x1600mm/1300x2800mm |

|

Drive System |

Imported Mitsubishi Servo Motor Drive |

|

Transmission System |

Pmi Linear Guide Rail, Precision Rack Drive |

|

Maximum Cutting Speed |

1800mm/s |

|

Cutting Material |

Asbestos, Rubber, Synthetic Resin, Ptfe, Etc. |

|

Cutting Tools |

Vibrating Kinfe, Round-Kinfe, v-Cut Knife, Milling Knife, Kiss-Cut Knife Etc. |

|

Cutting Thickness |

0.1-30mm (Subject To Specific Materials) |

|

Cutting Accuracy |

±0.01mm |

|

Repetition Accuracy |

±0.03mm |

|

Feeding Method |

Automatic Feeding(DT-2516A)/Manual Feeding(DT-1328F) |

|

Fixing Method |

All Aluminum Table Vacuum Adsorption |

|

Transmission Interface |

Usb/u Disk/Network |

|

Power Supply And Power Of Cutting Equipment |

220v/50hz 2.5kw |

|

Power Supply And Power Of Vacuum Pump |

380v 7.5kw/9kw (Optional) |

|

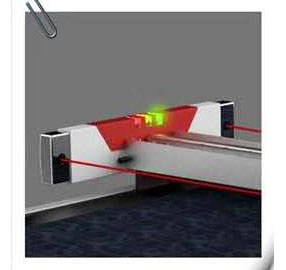

Positioning Method |

Infrared Laser, Ccd Camera (Optional) |

|

Safety Device |

Infrared Laser Induction, Safe And Stable |

|

Pneumatic Fittings |

Festo, Germany/Yadek, Taiwan |

|

Electrical Fittings |

Chint/Delixi |

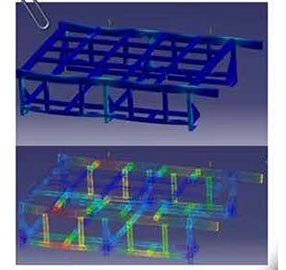

Seiko Welding Bed

Professional stress analysis to ensure the stability of the body and the strength of the whole machine

High temperature quenching relieves welding stress

Precision milling of large CNC machining centers ensures complete machine accuracy

Imported drive system with all-aluminum platform

imported PMI / HIWIN guide rail sliding table

Stable rack and pinion transmission

The all-aluminum platform is matched with the altitude cruise system to ensure the flatness of the platform, and the use of the felt is more durable

Imported MITUBISHI Servo

More stable performance at high speed

More torque and higher efficiency

High cutting accuracy, more precise and smooth curves

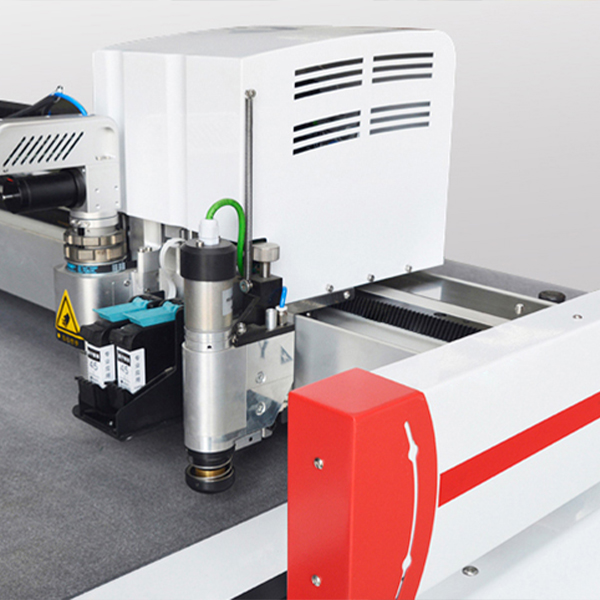

Modularized Cutting Tools

Free combination according to customer requirements

To meet various production and processing needs

Imported vibrating knife motors are more efficient

Imported pneumatic components

FESTO cylinder press material conveying more stable

AirTac solenoid valve is more flexible and durable

Intelligent security operating system

Intelligent interactive platform, simpler operation and more powerful functions

Anti-collision safety system and safety light curtain sensor system ensure safety first at work. Safety, we think more carefully

Datu oscillating knife cutting machine has unparalleled advantages in gasket making, it can cut the non-metallic gaskets which are made of non-metallic materials such as asbestos, rubber, synthetic resin, PTFE, etc. Machining these materials with vibrating knives can reduce costs and improve efficiency while providing high quality, short production cycles, and customized customer service. High cutting precision and no burrs.

1. 1800MM/S high speed, 0.01MM repeat positioning accuracy.

2. Mitsubishi servo motors, Taiwan Shangyin guide rails and other brand electrical components, double rack machines are more durable

3. Partition vacuum adsorption function, material fixation is more stable

4. The tool is modular, different materials are used with different tools, and the choice is flexible.

5. Equipped with a large visual intelligent edge inspection system, cutting and proofing are faster.

6. Intelligent nesting material typesetting software, maximize the use of materials.

7. Digital cutting scheme, no need to make die, save cost.

8. Multiple file format support (AI, PLT, DXF, CDR, etc.), is more convenient to use and interact with.

Applicable tools: vibrating kinfe, round-kinfe, Pneumatic knife.

Applicable models: DT-2516A DT-1328F

(1) One-year warranty policy.

(2) 7*24-hour online service.

(3) Provide lifetime free technology upgrade service.

(4) Free training in our factory, if time is not convenient, we can also provide complete training video.

(5) On-site technical support can be provided by negotiation.

Product detail pictures:

Related Product Guide:

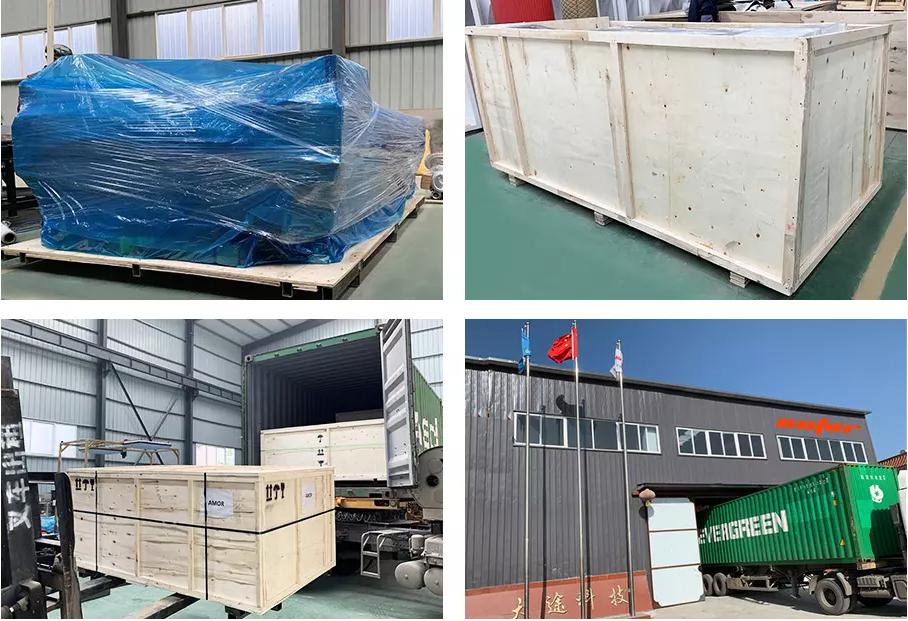

we are able to supply top quality items, aggressive price and greatest buyer assistance. Our destination is "You come here with difficulty and we offer you a smile to take away" for Factory Promotional Vibration Cutting Machine For Packaging - Gasket Digital Cutter – Datu, The product will supply to all over the world, such as: Congo, Egypt, Bangladesh, Our solutions have national accreditation requirements for qualified, good quality items, affordable value, was welcomed by individuals all over the world. Our goods will continue to improve inside the order and appear forward to cooperation with you, Really should any of those items be of interest to you, please letus know. We will be satisfied to provide you a quotation up on receipt of the detailed needs.

We have worked with many companies, but this time is the best,detailed explanation, timely delivery and quality qualified, nice!

-

Good Quality Fireproof Material Cutting Machine...

-

Trending Products Cutting Machine For Real Leat...

-

Reasonable Price CNC Knife Cutting Machine - G...

-

New Fashion Design For Packing Box Cutter - Di...

-

Low MOQ For Flexible Mat Cutter - Digital Cutt...

-

Massive Selection For PVC Coil Car Mat Cutter M...